The outer part of the water supply system, provided that it is shallowly buried in the ground, requires mandatory insulation. Otherwise, problems will arise with the supply of water in severe frosts. The system will just freeze. To keep the communication operational, high-quality thermal insulation is needed for water supply pipes. Insulation materials differ in the type of packaging (rolls, plates, casings) and the main component from which they are made.

The importance of insulating water pipes in the ground

- laying pipes above the level of soil freezing due to the features of the relief at the site;

- year-round residence of the family in the house, provided that the system is laid on the surface;

- living in cold-resistant regions where the average temperature in winter and spring does not rise above -10 degrees - here the level of soil freezing reaches 2-2.5 meters, which makes the installation of the water supply system labor-intensive.

If you do not insulate the water supply system with high quality in all its sections from the exit from the well / well to the entrance of the pipe into the house, at best, the communication will simply freeze until the first thaw. In the worst case, the tubes of the system will burst. Then serious repairs in the spring cannot be avoided, and these are additional financial costs.

According to SNiP, all underground communications must be laid below the level of soil freezing.

The basic principle of operation of all heaters is to create an air gap that retains heat. Therefore, all materials are classified as foamed.

Materials for thermal insulation

- good heat-saving ability and, accordingly, low thermal conductivity;

- durability;

- the ability to remove moisture;

- inertness to chemical and biological environments, the development of microorganisms in them;

- ease of installation;

- favorable price for the family budget.

The materials presented on the modern market largely meet these characteristics. The most popular are the following heaters:

- Glass wool. Most budget and options. It is lightweight and has good thermal insulation properties. However, the material is hygroscopic - it actively absorbs condensate and moisture. To protect the pipes from the effects of water, you will have to additionally lay a waterproofing layer on top and bottom of glass wool. This leads to additional costs. Mostly glass wool is used on HDPE plastic pipes. Popular materials of the brands Knauf, Ursa, Isover.

- Styrofoam (expanded polystyrene). Lightweight, strong, durable material. Perfectly retains heat and does not absorb moisture. For the convenience of users, the manufacturer offers ready-made half-cylinders of the required section for insulating water pipes. All that remains is to lay pipes in them and fix them with tape. In some cases, an additional protective coating of foil or polymers is provided in the foam shell.

- Foamed polyethylene (polyethylene foam). Relatively recently tested and trusted by masters material. Reacts calmly to temperature fluctuations, does not absorb moisture and retains heat well. It serves an average of 25-50 years. Prices per meter of insulation for water pipes in the ground are quite acceptable, starting at 28 rubles. The material is produced in the form of a casing for a pipe or in the form of half-cylinders.It is important to take into account that polyethylene foam sags under soil pressure, which is why it loses its ability to store heat. More often, such insulation is used for surface laying of pipes or for the inside of a water supply system.

- Heat insulating paint. A novelty in the field of pipeline insulation. The coloring composition is applied to the pipes. The layer thickness of 4 mm will fully replace the 8 mm mineral wool insulation. However, the cost of such a material is about $ 150. for 10 liters.

- Electric cable. Allows to heat the pipeline in severe frosts. It is wound along the surface of the system with an equal turn pitch. With the help of a heating cable, heat can be supplied to pipes laid at a level of 1 m from the surface of the earth. Electricity consumption averages 20 W / running meter. The cable can be laid both outside the system and inside. In the first case, the master will cope on his own, but most of the heat will go into the external environment. In the second option, you need to invite specialists. It is necessary to supply power to the electric cable only at subzero temperatures.

An alternative way to warm up the water main is the creation of an air gap. Corrugated elements are put on the tubes, the cross-section of which exceeds the diameter of the water supply system. As a result, an air gap is obtained, which is a heater. When the water moves in the pipes, a kind of heating is formed.

If the system is not used for 1-2 days, the effect of air insulation disappears on its own due to the lack of hydraulics in the pipeline.

Methods for insulating pipes underground

To ensure the heating of the outer part of the water supply system, the craftsmen resort to the following methods of insulation:

- laying a water supply system below the level of soil freezing by 0.5 m;

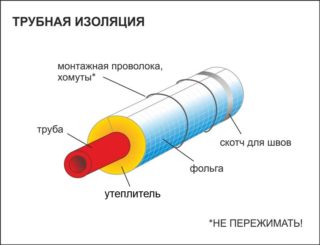

- insulation with covers made of expanded polystyrene and other heat insulators;

- heating cable laying;

- installation of a system from ready-made insulated pipes (they represent one tube in another - a larger one with a heater laid between them);

- air gap;

- a combination of several methods.

As a rule, several insulation options are combined, because part of the water supply entering the house or leaving the well / well is in different temperature conditions.

Insulation cost

Prices for insulation materials differ depending on their shape, main component and thickness / diameter. Average prices in Moscow:

| Insulation name | Manufacturer | Price, rub.) |

| Foamed polyethylene (pipes 2 m) Energoflex | Russia | From 14 rubles / m. linear depending on diameter |

| Polyethylene foam Thermaflex (pipe) | Netherlands | From 7 rub./m. linear depending on diameter and thickness |

| Mineral wool / basalt wool cylinder, unmachined | Russia | From 102 rubles / r.m. |

| Foam (polystyrene) shell | Russia | From 120 rubles / r.m. |

| Electric cable (7 m): Grand Meyer | Netherlands | RUB 1,920 for a skein. |

It is necessary to insulate all sections of the pipeline that are in the cold, including in unheated basements. In this case, it is forbidden to leave the slightest gaps between the material. When carrying out construction work, it is advisable to prepare a diagram on which the entire length of the water supply system is marked.

To protect the insulation from the attack of rodents who want to keep warm in the winter on the line, it is better to wrap the pipes additionally with a metal mesh or cover with a layer of plaster with broken glass added to it.