The range of pipes on the market for the installation of water supply and sewerage is very wide. Products are made of different materials and have different internal sections (nominal bore). Each diameter is designed for specific operating conditions. It is important not to be mistaken when choosing steel, cast iron, plastic water pipes with a diameter of 50 mm or more. Installation of the system, taking into account its nominal working pressure, is a guarantee of the reliability of the finished water supply or sewerage line.

Purpose of water pipes with a diameter of 50 mm

As a rule, tubes of the named section are used in such cases:

- Laying the inside of the sewerage system: drainage from the sink, bath, shower, bidet.

- Installation of the outer part of the water supply system, provided it is of considerable length and water supply to apartment buildings.

- The device of cable networks.

- Extraction of petroleum products (steel pipes).

- Installation of a heating system in the house.

- Gas transportation to residential buildings (steel, cast iron).

Also tubes with a cross section of 50 mm are used in the field of energy and mechanical engineering.

Specifications

Pipes with a diameter of 50 mm have different technical characteristics depending on the material from which they are made. But there are also similar parameters:

- Working pressure in the system for tubes of 50 mm - from 7-10 bar.

- The length of the pipes sold (polymers) is from 25 cm to 1.5 m. Steel - from 5 meters.

- Polymer products are dielectrics - they do not conduct electricity at all or in minimal quantities.

- The density of the polymer is 0.95-1.4 g / cm3.

- Service life from 50 years for plastic. From 30 years old - for steel and cast iron.

- The maximum temperature of the pumped-over media for polymers is +90 degrees. Metals - +110. It is optimal to transport water with an indicator not higher than +65 degrees. Otherwise, the pipes fail faster.

In terms of strength, PVC, HDPE tubes are seriously inferior to steel products. But with their correct operation / installation, the plastic can withstand serious loads in the form of soil pressure (when laying the outer parts of the water supply system).

Manufacturing material

There are several types of tubes with a cross section of 50 mm on the market:

- Steel tubes. The metal is durable and has been in good demand until recently. However, private craftsmen abandoned steel due to the laboriousness of the installation process. The metal tends to become covered with condensation from the outside, and from the inside it becomes overgrown with limescale (when transporting hot water). Steel is prone to corrosion. An additional disadvantage of steel pipes is high electrical conductivity.

- Cast iron products. Until recently (the end of the 20th century), only such tubes were used in private construction. Now they are also giving way to lighter, equally durable materials. Although cast iron has been serving for 50 years, its tendency to siltation and corrosion plays a negative role. In addition, the installation of metal pipes requires welding or threaded connections, and this is additional labor costs.

- Polypropylene pipes with a diameter of 50 mm for cold water (if they are used for laying an external water supply system). This material is the most popular. It has good plasticity and is prone to linear stretching. Thanks to the perfectly smooth inner walls, it transports large volumes of water or wastewater without any problems. In this case, the system is not silted up.

- PVC pipes.The most common version of products for the device of the inner part of the sewage system. Capable of pumping both cold and hot water / wastewater. Resistant to mechanical damage, lightweight, extremely easy to install.

- HDPE (low pressure polyethylene) products. They behave well even when the water in the system freezes. If you take tubes made of cross-linked polyethylene, you can equally efficiently transport both cold and hot water through them.

It is not recommended to select pipes without preliminary engineering calculations. At a minimum, it is advisable for a private master to look into SNiP.

Criterias of choice

When buying pipes with a cross section of 50 mm, it is important to be guided by the following indicators:

- Appointment of products. For private construction or the laying of internal communications of a short length, it is better to take PVC pipes. If we are talking about a more global installation of highways, use steel or HDPE products.

- Working pressure of each material. The standard centralized water supply operates at rates from 3 to 7 bar (4 bar is considered the norm). But the peak values can occasionally reach 10 bar (the first test is always carried out at a pressure of 12 bar). Pipes need a safety margin.

- Ease of installation. The simplest are PVC tubes. When it comes to metal, the communication process is many times more complicated.

If you take pipes under the screed, it is better to give preference to polypropylene products.

Installation features

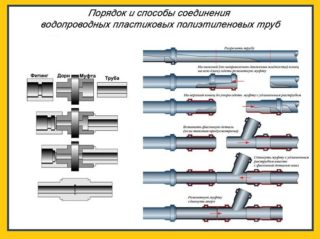

- PVC are joined in the socket using special rubber sealing cuffs. The gasket is pre-treated with silicone sealant for greater reliability. Then the next section of the tube is driven all the way into the socket. In this case, it is important to arrange the elements so that the socket looks in the direction of movement of water or wastewater. If a sewer system is being installed, do not forget to make it slope towards the common riser at the rate of 1 cm for each meter of the line.

- Polypropylene pipes are brazed using special equipment with nozzles and the same PP fittings. For joining, the soldering iron with the nozzles is heated to a certain temperature, the end of the pipe is put on it until the material softens. Then the tube is driven into the fitting until it stops. Cooling polypropylene forms a sealed connection with a clamp made of the same material.

- Polyethylene tubes are joined using electrofusion fittings. The sleeve is put on at the junction of two pipes. A special spiral built into the cuff heats it up until it melts easily. The result is a strong, sealed connection.

- Steel pipes are subject to mandatory welding during installation. Cast iron products are either boiled or joined in the socket using the caulking method.

When constructing any highway, sharp turns, straight or sharp corners should be avoided. Correct any bends with swivel fittings. On the sewer main, it is advisable to install an inspection hatch in a place accessible for inspection. This is especially important if the pipes are laid under decorative trim or screed.

Pipe price per meter and piece

Prices per meter of HDPE pipe with a diameter of 50 mm or tubes made of steel, cast iron, PVC vary depending on the region of sale, but insignificantly. The approximate cost of products:

- steel tube - from 306 rubles / meter;

- cast iron (length 2 meters) - 1,440 rubles / piece;

- PVC - from 24 rubles / piece. depends on the length of the product;

- HDPE - from 33.60 rubles / meter.

When buying polymer pipes, pay attention to the uniformity of their color. Whitish spots on the surface of the product indicate that the technology of its production has been violated. Over time, such a tube will not withstand exploitation.