Steel water pipes are mainly installed in aggressive places where the mains pass. Such structures are highly durable and resistant to possible mechanical stress. However, such options are not suitable for domestic water supply, therefore, they are focused only on industrial facilities.

Regulatory Requirements

Despite the high popularity of PVC pipes, steel pipes are not inferior to them. Since engineering networks supply water to apartment buildings and private houses, they must comply with some SNiP standards, which testifies to the safety of these structures for humans.

- GOST 30732-2006. One of the main regulatory documents for steel plumbing structures. Such raw materials are usually used for laying a pipeline in soil conditions. Products are suitable if the coolant has a constant temperature of no more than 140 degrees. Short-term increases in t up to 150 degrees are also allowed.

- GOST 9567-75. This marking of the steel structure indicates that it is a high precision steel structure. The product can be hot rolled or cold worked. Also, pipes made of steel of this type are divided into galvanized and chrome-plated.

- GOST 2591-2006 (88). The assortment indicates that the pipe is hot-rolled. The design has a square or rectangular cross-section with sides from 6 to 200 mm. Larger structures with a similar cross-section are made exclusively to order.

The parameters of metal structures, which have a state standard, are always individual, therefore, before starting production work, it is necessary to determine the dimensions of the future highway. The use of steel pipes is allowed in the case of the construction of pressure stations, water pipelines in seismically unstable zones, for laying at the bottom of a ravine.

Types of steel pipes

As a rule, metal structures are classified according to the manufacturing method, from where they take their individual name. For industrial and domestic purposes, the following options can be used:

- Cast. The rolled products are manufactured by means of pipe-casting machines. This type of manufacture is provided for exclusive purposes, since such designs are used in some industrial sectors.

- Seamless. Pipes are produced using pressed machines or specialized blanks. Usually, such options are not applicable to create a plumbing. They are more expensive and are reliable for the organization of highways in the chemical or petroleum industry.

- Welded (electrowelded). The most popular rental for water mains. Such products are made of steel strips, which are cut, and then bend under high temperature.

There are longitudinal seam pipes that are only suitable for plumbing. Such products have more than a hundred possible diameters.

Each design must correspond to its indicator, depending on which it is divided into groups.

- Plain steel pipe. High strength metal construction. The price is too high, but it is justified by its characteristics. A wide range of shut-off valves is allowed.

- Galvanized pipeline. The steel structure has an inner and outer zinc layer that protects against harmful environmental influences.Such products are suitable even when there is a risk of increased deformation.

- Corrugated pipeline. Stainless steel resists many chemical and mechanical stress. Often, such rental is used in problem areas to avoid water leaks. A flexible pipe is usually installed on faucets when arranging a home plumbing.

- VGP pipeline. Manufactured from a special steel alloy. Usually, air pipelines are made of such rolled products, since they can withstand changing climatic conditions. The material is made from carbon steel.

Based on the type of pipeline chosen, it is necessary to buy fittings and other parts. The main thing is that fittings fit to it in diameter.

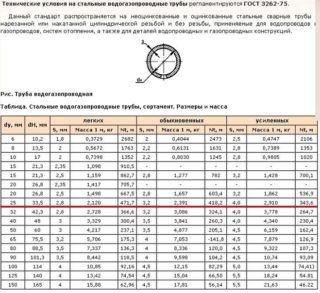

Technical Specifications of Steel Plumbing Pipes

The assortment varies from the minimum diameter to the indicators with large dimensions. These two types are used for different purposes. A table of dimensions of steel water pipes in accordance with GOST will help determine the design option.

Conditional pass | Outside diameter | Wall thickness | Weight 1 m, kg | ||||

| lungs | ordinary | reinforced | lungs | ordinary | reinforced | ||

| 6 | 1,8 | 2 | 2,5 | 0,37 | 0,4 | 0,47 | |

| 8 | 2 | 2,2 | 2,8 | 0,57 | 0,61 | 0,74 | |

| 10 | 2 | 2,2 | 2,8 | 0,74 | 0,8 | 0,98 | |

| 15 | 2,35 | — | — | 1,1 | — | — | |

| 15 | 2,5 | 2,8 | 3,2 | 1,16 | 1,28 | 1,43 | |

| 20 | 2,8 | — | — | 1,42 | — | — | |

In addition to the dimensions (in inches or mm) and the mass of rolled metal for the construction of a water supply system, it is also necessary to take into account the operational characteristics of the pipe. You can find out about this from the labeling or just ask the seller.

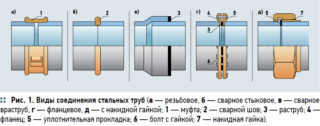

Connection and installation features

- using a welded seam;

- welding of flanges to the ends of the branch pipes;

- by welding with the formation of loops;

- by squeezing and chasing.

During installation, the engineer must take a responsible approach to the rules for the construction of main water pipelines, since they are usually used in an area with maximum pressure and high temperature. The water and gas pipeline should become in this way only if it is designed to run water through it.

Advantages and disadvantages

Steel pipes are considered to be among the most durable. They are used in various conditions on the street, less often in household premises (apartment, house). The advantages include:

- long service life even in aggressive conditions;

- perform equally well when used for hot and cold water supply;

- the presence of a protective material;

- using simple welding to create joints;

- compliance with all necessary GOSTs according to SNiP.

Of the minuses, it is worth highlighting the susceptibility to corrosion due to improper operation of the finished structure. The presence of rust negatively affects the taste of drinking water, it is enriched with harmful metals. Rust tends to form on the outer walls of the pipes and on the inside.

When using metal water pipes, there is a high risk of siltation of the lumen, as a result, a breakthrough is possible, and, as a result, a replacement of the structure. Such a structure cannot be cleaned, especially if the narrowing of the lumen has occurred in its rotary part.

While in the ground or under any other conditions, steel pipe structures retain their attractive appearance even without painting.

Price per meter

Since steel structures are different and are classified according to different criteria, the price per meter of metal pipes for plumbing will vary. Simple rolled products with a conventional cross-section will cost several times less than corrugated ones. Popular types:

- steel pipe "VGP" with a diameter of 50 mm - estimated cost up to 335 rubles;

- steel pipe with a square section with sides of 20x20 mm - the price is 100 rubles;

- seamless steel pipe - cost 650 rubles;

- galvanized pipe with a circular cross-section with a diameter of 20 mm - an approximate cost of 700 rubles.

Otherwise, all prices for engineering structures vary depending on the manufacturer's company and the region where they are sold.