Various plastic and metal fittings are used in water supply systems. The design and features of their application depend on the goals. You should consider the main types of connecting elements and understand the characteristics of highways made of popular materials in order to mount a high-quality pipeline.

The use of plastic pipes and fittings in water supply

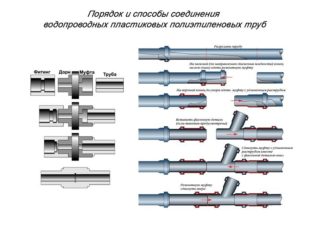

Install the water supply system using connecting elements - fittings. When using polyethylene products, it turns out to create engineering systems without the use of complex equipment. This solution reduces installation labor and waste.

Types of connecting elements

- fittings - required to connect pipes with flexible bends;

- plugs and caps - used when closing the end holes;

- adapters are installed when joining sections of different diameters;

- crosses - necessary to separate the flow in several directions;

- tees, or collectors - are used to create branches from the main line;

- couplings - allow you to lengthen pipes in a straight line;

- elbows and corners - used to change the direction of the trunk.

Depending on the material of manufacture, fittings are divided into bronze, copper, steel, cast iron and brass. Polypropylene and PVC products are used for flexible hoses.

By the method of joining, fittings are:

- compression;

- flanged;

- threaded;

- welding;

- crimp.

When installing plumbing equipment, all types of pipe fittings are equally used. When choosing components, it is necessary to focus on the estimated pressure in the water supply system and the diameter of the abutting sections.

Manufacturing material

Pipes for water supply, depending on the material of manufacture:

- Steel. Connected with threaded fittings. The installation of such products requires the use of special tools - adjustable and gas wrenches, mechanisms for threading, a hacksaw. In addition, welding equipment and sealant tape are required. The advantages of steel lines are their strength and durability. Among the disadvantages are the complexity of installation and susceptibility to corrosion.

- Copper. They have a long service life (from 40 years) and high resistance to temperature extremes. The disadvantages include the need to use a soldering machine. If any area is damaged, it must be cut out and the water supply reassembled.

- Reinforced plastic. They have 3 layers: outer and inner from plastic, main from metal.The advantages of metal-plastic include high flexibility, no corrosion, quick installation and ease of repair.

- Polypropylene. Can be reinforced (for hot water supply). Sections of the network are connected using tees, adapters and threaded couplings. The service life of polypropylene is 50 years. The disadvantages of the material include low flexibility. If a defect is found on the site, it is cut out, and the pipeline is reassembled.

- Made from cross-linked polypropylene. They are resistant to high pressure and temperature extremes, sufficient sound insulation and low thermal conductivity. Separate sections are connected by pressing the press sleeve. Fittings are reused. The only drawback of cross-linked polypropylene products is the higher cost than the usual variety of modern material. The optimal prices for them can be found in the Rehau catalogs.

- PVC pipes and fittings for plumbing are the most affordable and reliable. Resistant to water hammer, immune to the formation and development of bacteria, not affected by ultraviolet radiation.

PVC pipes and fittings are more often used for hot water supply networks.

Specifications

- Density - 0.91 kg / cm3. Despite the fact that the indicator is minimal against the background of similar materials, the products are distinguished by high strength and hardness. In addition, polypropylene is not susceptible to abrasion, due to which it tolerates well the impact of abrasive particles.

- Low coefficient of thermal conductivity. Condensation does not accumulate on the surface.

- High strength. However, sharp kinks and strong pressure lead to cracks. You need to change the shape of the products slowly.

- Resistance to destruction in aggressive environments. The risk of material damage arises from contact with strong acids or prolonged heating.

The dimensions of propylene pipes and fittings for water supply depend on the material of manufacture (PPR, PPH, PPB, PPS) and can be from 16 to 1200 mm.

Main selection criteria

The laying of water supply systems involves the selection of fittings and pipes of a suitable diameter. When buying products, you should ask the seller about the availability of permits from the manufacturing plant. Plastic pipes and fittings for plumbing are less expensive and lightweight, so they are more often used in residential construction.

It is worth paying attention to the assembly of the assemblies - the distance between the flanges should be such that it was possible to easily tighten the bolts and install the valves while maintaining the tightness of the system. If this condition is met, the water supply system will be resistant to a pressure of 12 atmospheres, which will eliminate the risk of leaks.

Since polyethylene pipes are fusible, a soldering iron with a low temperature is used during the welding process. To connect such sections of the network, welded and compression fittings are used. When installing large diameter pipes, special heating devices are used.

Installation steps

There are no special technological subtleties in the process of installing polypropylene pipes, however, in the absence of work skills, difficulties may arise with the operation of the pipeline in the future. Sequencing:

- Cut off the pipe section.

- Deburr the cut site.

- Select and fit the required fitting.

- Place the appropriate tip on the polypropylene soldering iron.

- Switch on the device and wait for it to heat up.

- Simultaneously insert the pipe end and the connecting piece into the soldering iron nozzle and then wait a few seconds (the time depends on the wall thickness).

- Remove the fitting and the section of the water supply from the nozzle and manually connect by inserting one element into the other until it stops.

The peculiarity of installing a polypropylene water supply system is the need to quickly perform all actions.