Stainless steel pipes are used for laying water supply and heating systems. They have a number of advantages over other materials, which makes communications durable and hygienic. The service life of stainless steel products can be up to 400 years. At the same time, ordinary carbon steel requires replacement after 10-15 years, so it is gradually being phased out. However, stainless steel pipes have their drawbacks. These should be considered before purchasing equipment.

Industries of application

There are a large number of stainless steel pipes on the market. They can perform a variety of tasks, from industrial to domestic.

Spheres of application of stainless steel products:

- installation of water supply networks;

- arrangement of heating systems;

- laying of gas communications;

- creation of fire extinguishing systems.

On an industrial scale, steel is used in the furniture, fuel, medical, automotive, chemical, instrument-making and food industries.

Regulatory Requirements

There are two types of stainless steel pipes: seam (welded) and seamless. Each of them has its own regulatory requirements - the state standard (GOST).

Suture pipes in the documents are called electrowelded. To make them, a sheet of steel is twisted and the edges are welded together. The seam runs along the entire pipe. The larger the product, the more sheets are required, and the more seams you will get.

In the manufacture of stainless pipes, manufacturers rely on the requirements of the standard 11068-81. They determine the size of the wall and the correct diameter. In order for the pipe to meet the specified parameters, molding, calibration, etc. are used.

Seamless pipes produced by rolling. To give the product the necessary shapes, a special rod is used, on which the workpiece is put on. Production is regulated by the following GOSTs:

- for oil and fuel lines - 19277-2016;

- for hot-deformed pipes - 9940-81;

- for cold and heat deformed - 9941-81.

They are distinguished by the processing temperature of the workpieces. The standard also defines the minimum and maximum deviations in length, wall thickness, curvature.

Specifications

steel grade

Steel grade AISI 316Ti is distinguished by its resistance to acidic environments. This property does not change even at elevated temperatures; therefore, products from this alloy are used in the petrochemical industry. In addition, welded pipes have a long service life.

In the petrochemical and metallurgical industries, pipes are mainly used from AISI 904L steel. In the production of heat-resistant equipment, steel products are used that are resistant to high temperatures. Among them are the brands 310S, S31000, S31008, S31009.

The most corrosion-resistant steel for pipe production is AISI 321. It contains chromium, titanium, nickel. The material is ideal for laying pipelines, as it does not affect the quality of the water.

Sectional shape

Depending on the shape of the section, the pipes are oval, square, rectangular, etc. In the metal rolling industry, they are called profile.Each type of section is used for its intended purpose: some for the installation of building frames, others for the production of furniture, decoration, agriculture and others.

Modern manufacturers also produce stainless steel pipes of more complex sections: round with a hexagonal hole, trapezoidal, triangular, hexagonal, parallelogram, rhombic, hexagonal nut.

Diameter

Longitudinal welded stainless steel pipes have an outer diameter from 10 to 1420 mm, and a wall thickness from 1 to 32 mm.

Standard sizes of spiral welded steel products are regulated by GOST 8696-74. Outside diameter - from 159 to 2520 mm, wall thickness - from 3.5 to 25 mm. The segments are made in lengths from 10 to 12 meters.

Hot-deformed seamless pipes in outer diameter range from 57 to 325 mm, their wall thickness - from 3.5 to 32 mm.

Criterias of choice

When choosing a suitable stainless steel pipe, you need to know:

- profile;

- thickness;

- steel grade;

- manufacturing technology.

The choice of parameters for rolled metal products will depend on mechanical and chemical loads and the duration of their exposure.

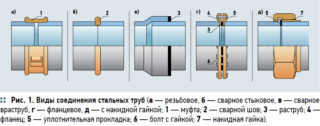

Features of installation and connection

- welded;

- the use of flange-type connecting elements;

- crimping.

Work should only be carried out by a qualified specialist using professional equipment. The process is usually carried out with a tungsten electrode, and the welding itself is performed in an inert gas environment.

There is also a more modern method - plasma welding. It allows you to connect pipes with maximum quality. But the equipment for carrying out the work is quite expensive, so its purchase is justified only for construction organizations and companies with related activities.

Advantages and disadvantages

Advantages of stainless steel pipes:

- do not collapse during water hammer;

- bend at any angle, which simplifies installation in cramped conditions;

- durable and resistant to corrosion;

- have an almost unlimited shelf life;

- lungs.

Steel structures have a wide range of pressures and temperatures, so they are suitable for a wide variety of needs. But they also have their drawbacks. For example, high cost. But it is entirely justified, since the replacement of pipes will not be needed earlier than in 200-400 years.

The cost of stainless steel products

The price for stainless steel water pipes is billed per linear meter or kilogram. The determining factor is the quality of the material. Many brands contain copper, titanium, chromium, nickel and other metals in different proportions. They give the structure additional strength and resistance to corrosion, thereby increasing the cost of the finished product. Also, the price is influenced by the diameter of the pipes, the type of processing. Polished items are more expensive.

Retail prices:

- 0.68x0.16 mm 12X18H10T seamless, matte - the price is about 1590 rubles / kg;

- 6x1 mm 12X18H10T, non-w, matte - about 570 rubles / kg;

- 10x1.5 mm AISI 304 (08X18H10) e / s, matte - about 135 rubles / running meter;

- 10x10x1 mm AISI 304 (08X18H10) e / s, mirror - about 230 rubles / r.m .;

- 14x1.5 mm AISI 304 (08X18H10) e / s, polished - about 150 rubles / running meter;

- 25x1.5 mm 10Х23Н18 b / w, matte - the price is about 580 rubles / kg.

Among manufacturers, give preference to the best proven brands. Popular are KOFULSO LTD (South Korea), GOFRA-FLEX (South Korea), NEPTUN IWS (Russia). They have been on the market for a long time and have already won the trust of consumers.