Polyethylene pipes are used in the construction of drinking water and sewerage pipelines. They are cheaper analogs of steel structures, but they are not inferior in strength, and in some cases even surpass metal. It is important to know how a high-quality pipe is made and how much it costs, so as not to buy a counterfeit that will not work out its allotted time. Certified products have parameters that must be observed during manufacturing - composition of raw materials, wall thickness, fluid pressure that the finished product can withstand.

Scope of HDPE water pipes

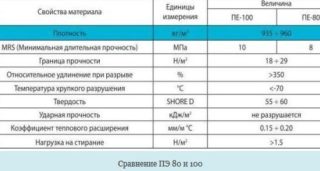

Low-pressure polyethylene is a durable material from which pipes with different properties are obtained with various technological nuances. The most popular are PE 80 and PE 100. Despite the fact that PE 80 is the predecessor of PE 100, they differ greatly in their technical characteristics. Because of this, difficulties arise in choosing, since not even all masters know exactly how these two brands differ. Many experts believe that PE 100 behaves worse during the soldering process, but this is a misconception: a higher temperature is needed for a high-quality connection of two pipe sections. Most often, there is simply no such equipment in the arsenal of a company that is engaged in laying pipelines, therefore it is advised to choose PE 80, although this type is inferior to PE 100 in all respects, except for price.

PE 80 does not tolerate environmental influences and quickly loses its characteristics, especially plasticity under the influence of ultraviolet radiation. This means that any minor mechanical damage can lead to cracks, ruptures and failure of the pipe section.

HDPE products are used in the construction of highways for the transportation of drinking water. The pipes are marked with a blue line. The rest are intended for laying sewer wiring. A large number of connecting elements are made for them from the same material - bends, tees, although the pipes are connected qualitatively by soldering.

Products with a small diameter are used in the arrangement of underfloor heating in houses, greenhouses.

The material is resistant to corrosion and does not collect sediment inside, which makes it possible to operate it for up to 50 years. The temperature range that low-pressure polyethylene withstands is from -50 to + 55 degrees.

Advantages and disadvantages

- practically does not need care and maintenance;

- does not oxidize and does not emit harmful substances into the liquid;

- less likelihood of condensation on the surface, since the material has low thermal conductivity;

- when water freezes inside, polyethylene expands in diameter and does not break;

- the products are lightweight, therefore they fit without the involvement of construction equipment;

- welding of plastic takes less time and is more reliable;

- fewer welds will be required, since polyethylene pipes are longer than metal ones;

- reduction of costs by 45% when replacing pipe sections;

- scale does not form on the inner surface, since the walls are very smooth and the material is chemically inert.

Disadvantages:

- Plastic pipes can be damaged by soil mobility and therefore require additional protection.

- Availability of special equipment for welding.

- UV light can damage products without a special protective coating.

- Due to temperature limitations, HDPE pipes may not be used everywhere.

The main advantage of HDPE is the price. Raw materials for the production of pipes are cheap, and products made from them are able to compete with more expensive materials in terms of their characteristics.

Types and technical characteristics

PE 80 and 100 are innovative materials that surpass PE 63 in all respects, therefore they are used in all areas - for the arrangement of pressure and non-pressure sewage systems, water supply systems, gas mains. Manufacturers produce more PE 100 products, since its characteristics are more perfect in relation to PE 80.

Advantages of PE 100:

- higher density, so the wall thickness can be less;

- the throughput is higher all due to the same inner diameter;

- less pipe weight at the same pressure and throughput;

- cracking resistance of PE 100 is several times higher, therefore the service life is longer;

- the material can withstand very low temperatures, which makes it possible to use it in all regions of the country.

Pipes of the PE 80 brand are cheaper, but you can save money only if the communications are built from products of small diameter. For example, drip irrigation systems for greenhouses or suburban garden water pipelines located at a shallow depth. If a pipe section is damaged, it can be quickly replaced.

Criterias of choice

Any manager in a building materials supermarket will advise you to choose the PE 100 brand. But differences in material are not everything. The following parameters should be taken into account:

- For what type of pipeline are pipes needed: for drinking or industrial water, sewerage. There are 9 types of water pipes. Operated at temperatures from 0 to 40 degrees. Hot water products are colored red.

- Estimated pressure to match the appropriate density. For storm and free-flow sewerage - one type. For pressurized water supply - another.

- The number of water intake points in the house and the number of residents.

- Laying method - surface or underground. If it is decided to place the pipes on the surface, they must be protected by a special sheath from ultraviolet radiation and mechanical damage.

- Depending on the degree of soil mobility, it is necessary to choose the strength factor of the products and additional materials for laying in the soil.

Before purchasing, it is necessary to inspect the appearance of the pipes. They must be smooth and free from damage. It is advisable to buy all parts from the same manufacturer so that the dimensions of the pipes and fittings fit together.

Dimensions and markings

Each of the three grades of polyethylene has dimensions:

- outer diameter from 1 to 120 cm;

- wall width from 0.5 to 5.3 cm;

- inner diameter that determines the throughput.

The higher the pressure in the system is planned, the thicker the walls of the products.

The dimensions of HDPE pipes for cold water supply differ depending on which diameter they have. Small section products are sold in coils. Wide ones are cut into equal pieces up to 12 m.

For domestic water supply and sewerage systems, polyethylene pipes with a diameter of 50 and 110 mm are usually used. The external drainage system depends on the load on the sewerage system, taking into account the number of residents.

Requirements in accordance with GOST

In terms of quality, HDPE pipes of different markings must comply with the requirements of GOST:

- The inside and outside surfaces must be smooth. The presence of waviness should not deduce the diameter beyond the permissible norms.

- The end surfaces are smooth, without air inclusions, cracks, notches.

- The elongation of the pipe is no more than 3% after heating.

- Resistance to constant pressure for 100 hours at a temperature of 20 degrees.

- At 80 degrees resistance of all brands for 165 hours at constant pressure.

- According to safety requirements, the ambient temperature should not exceed 300 degrees. The material is classified as combustible.

- Polyethylene does not release harmful toxins into the environment. When working with it, no additional security measures are required.

- Waste after installation is harmless. They are brought back to the manufacturing plant and recycled.

Products are subject to preliminary testing prior to shipment to consumers. Inconsistency in at least one item requires revision and retesting.

Installation features

Polyethylene pipes are connected in one of the following ways:

- welding using the SSPT apparatus;

- fittings;

- electrodiffusion or electrofusion welding.

Some firms do not have suitable equipment for working with PE 100 due to its high cost. The device costs about 2.5 million rubles for large-diameter pipes. Without it, the quality of the connections will be unreliable. Therefore, it is recommended that buyers purchase a cheaper and less durable PE 80. In this case, it is better to use another technology for joining polyethylene pipes - fittings. It will cost more through the purchase of additional parts, but the overall system will be more reliable.

Laying in the ground is carried out below the freezing level. This indicator varies depending on the longitude of the location of the region. When embedding the wiring in the ground, it is not advisable to use compression fittings. The welding method in this case has an advantage - it is more reliable and durable. For concealed installation, the pressfitting method is suitable. Press fittings are crimped on the outer surface of the pipe with a special tool.

It is also not recommended to lay sections with joints in the ground or equip inspection wells in such places in case of need for repairs. Although, there are very few cases of divergence of joints. They occur when welding is carried out by a handicraft method, without using the necessary equipment.

There should be no stones or sharp objects in the ground. They can cause premature pipe damage and leakage. The best option is laying on a sand pillow.

In the northern regions, polyethylene is additionally insulated with mineral wool or other materials. This contributes to an increase in the service life of the products.

The cost of polyethylene pipes

Prices for polyethylene water pipes compare favorably with steel or cast iron. Firstly, delivery and installation will be cheaper, since construction equipment is not involved. It is not advisable to save on the welding machine. If you plan to install the system yourself, you should take into account the cost of the welding device - for small-diameter pipes it will cost about 95 - 135 thousand rubles.

The price of the pipes themselves depends on the amount of consumables. This is influenced by the outer diameter and wall thickness. Additional costs may arise if you decide to buy products with a UV protective coating. Surface mounted fittings also add value to the overall structure.