Ultrafiltration and ultraviolet light are different things. Irradiation, that is, water purification with ultraviolet light, is the effect of a certain spectrum of light on bacteria and parasites, in which they are destroyed. This should be done at the final stage of liquid purification. Ultrafiltration or superfiltration is the use of a filter with very small pores, through which even viruses cannot pass. You should consider this method in more detail.

Ultrafiltration - definition and scope

All the requirements for preliminary water treatment are met only by membrane technologies - nanofiltration, reverse osmosis systems, a UV filter for water. Compared with the old methods - electrocoagulation, installation of ultraviolet disinfection of drinking water, chlorination - they are the most progressive and every year they give an increase in the amount of high-quality clean drinking water.

Ultrafiltration is the removal of suspended particles using ultra-fine pore filters. For example, the size of the virus is 0.02 microns, and the pores are 0.01 microns.

Before final cleaning, the liquid should not contain substances that affect the turbidity index - organic and inorganic contaminants. Therefore, at the initial stage of the process, ultrafiltration units are used, which purify water from 99.99% of substances. This saves subsequent filters and extends the service life.

The pore size will vary depending on the original fluid quality. If the water is withdrawn from surface sources, a better filter is required. When supplying water from underground wells, filters with increased porosity can be dispensed with.

Industrial UV filters are used in the production of wine, cognac products, as well as liquid food products - milk, juices. At oil refineries, they are installed to purify wastewater from petroleum products and oils. In large quantities - cassette or cascade method - filters are used in factories for the production of drinking water.

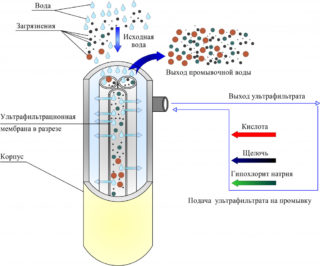

Operating principle

The main task of the ultrafilter is to disinfect and clarify the liquid. This happens when water passes through the membrane. There are two ways - pressurized and non-pressurized. In the first case, the liquid passes through the membrane layer under pressure created by the pump, in the second, a rarefied space is created from the inside, and water is sucked in by the membrane.

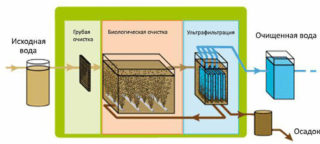

The filter modules are usually arranged vertically to distribute the liquid evenly. The system elements are arranged in the following sequence:

- Water intake or supply pipeline.

- Pressure regulating pump.

- Membrane filter.

- Clean water tank or pipe.

- Pipe for discharge of waste and liquid after flushing the system.

The diaphragm is often clogged, therefore, when debugging the equipment, the specialist sets the optimal pressure and frequency of flushing the system. Flushing takes place in two ways - with a counter flow from an already purified liquid or by drainage from a water intake pipe. Waste is discharged into a separate container and disposed of.

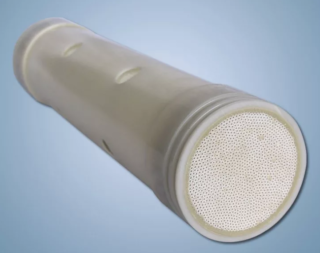

Membrane materials

The main material used for the manufacture of a fine-pored membrane is polysulfone.This substance is resistant to acids, alkalis, alcohols. The new generation polysulfone withstands temperatures up to 200 degrees, gives little shrinkage and expansion with changes in temperature conditions, therefore it is used for the manufacture of parts that must keep their shape in any conditions. The fibers are hollow in structure, so the material is used for the manufacture of reverse osmosis filters and in ultrafiltration systems. The weak point of polyestersulfone is chlorine compounds, therefore, manufacturers distinguish work with a chlorinated liquid, calculated in hours, as the main criterion for service life.

Ceramic membrane is considered to be more durable. It can last for decades as bacteria cannot damage it. They clean it with ordinary detergents - vinegar, soda or even mustard powder. In maintenance, ceramics are cheaper, since there is no expense for disinfecting substances with which the rest of the membranes are treated so that colonies of microorganisms do not form on them.

Water ultrafiltration system device

The general scheme of the system, which includes the ultrafilter, contains a coarse mechanical filter that retains sand, silt, bottom sediments, and coarse organic matter. Further, the liquid under pressure through the inlet pipe goes directly to the UV filter, the main cleaning process begins. Water seeps through the porous membrane and enters the outlet. There are systems in which a reverse flow of permeate (filtrate or pure water) is possible in order to wash away the layers of accumulated organic matter from the membrane. This process is configured and works automatically. Depending on the degree of contamination of the source liquid, rinsing is done more or less often.

Further, the filtrate enters the reverse osmosis system and undergoes further post-treatment. UV lamps for water treatment are usually not required, since at this stage all dangerous bacteria and viruses are removed from the liquid.

Advantages and disadvantages of the method

The ultrafiltration method allows:

- maintain the quality of drinking water at a high level, avoiding fluctuations in the direction of deterioration of indicators;

- reduce the cost of water for the population due to a simple cleaning mechanism;

- reduce the level of hazardous compounds that are formed when using chlorine;

- install small-sized installations in an apartment or apply large systems for high-rise buildings or separate areas of the city;

- select the installation according to the pressure in the pipeline;

- save energy.

Filtered water contains all useful salts, so no mineralization is required. There are no heavy metals in the purified liquid.

The most significant disadvantage is the filter's inability to retain dissolved inorganic compounds - sodium, calcium. Industrial fluids may also contain other hazardous substances, molecules of which do not exceed the pore diameter of the membrane. It is impossible to soften water using this method, therefore other filters are used.

The use of a UV filter is preferable for non-chlorinated water, as chlorine damages the fibers and renders the material unusable. To neutralize chlorine, other cleaning methods are used, for example, the ion exchange method.

Criterias of choice

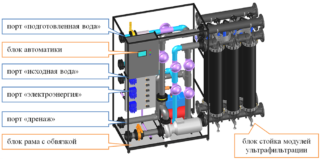

On sale you can find household compact models and larger ones, intended for enterprises, high-rise buildings.

To choose the right ultrafilter, you need to consider:

- the family's need for clean water - how many liters per day are consumed - the cost will depend on this indicator;

- what material is used in the manufacture of the membrane - the service life and the ability of self-healing of the cleaning mechanism depend on this;

- how much the product can withstand hot water;

- pressure in the city water supply;

- pore size, which will determine how well the water is purified.

Since filters of this type are not cheap, it is important to take into account all the indicators so as not to overpay. Perhaps the quality of the water in the city system allows it to be used for bathing and washing, as well as washing dishes, but for consumption inside, an additional filter must be installed. In this case, the smallest option is suitable, which is installed in an apartment or office.

Installation and connection

If the filter is installed only for the production of drinking water, it is necessary to buy an additional tap, which will be installed next to the main one. Sometimes the owners want to have a supply, so a hydraulic tank is mounted between the tap and the filter, into which the filtrate enters.

Filter unit price

The cost of ultrafilters of various capacities can be considered on the example of products that are manufactured on the basis of the D.P. Mendeleev Russian University of Chemical Technology. The apartment option costs about 19 thousand rubles and is adapted to urban water supply systems. More efficient installations for apartment buildings, private cottages cost from 23 to 47 thousand rubles. Industrial filters are the most productive, their cost is about 80 thousand rubles.

For large enterprises specializing in the purification of liquids, several filters are purchased, which are combined into cassettes. For insurance, spare blocks should be used in case the working filters are under repair or scheduled maintenance.