For autonomous water supply in a private house, a well is usually chosen. The quality of the liquid obtained from it is much better than when the intake comes from an open reservoir or well. When creating and operating a hydraulic structure, it is important to control the static and dynamic water level in the well.

Static and dynamic level concepts

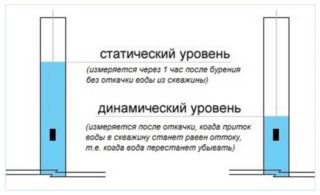

The static indicator is equal to the distance from the earth's surface to the level at which the water mirror in a deep well is located at rest, that is, when the pressure equipment is not working. Knowledge of this indicator makes it possible to estimate the stock of underground sources. The characteristic is influenced by the pressure value inside the formation, and not by the section of the mine of the artesian hydraulic structure or its depth.

This value is not constant, it depends on the following factors:

- abundance of precipitation;

- number of water consumers,

- intensive pumping of water.

The measurement is carried out no later than an hour after the disturbances in the well have calmed down, for example, the pump has been turned off. Also, do not take measurements after heavy rainfall, so as not to receive incorrect information. In surface and sandy intakes, the indicator usually coincides with the level of subsoil waters.

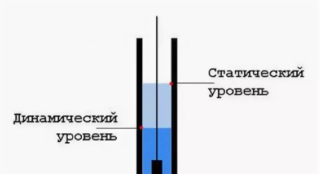

The dynamic level depends on the static characteristic, with the help of which the immersion depth of the borehole pump is determined. It is measured with the pressure equipment switched on from the earth's surface to the water surface. To prevent the pumping unit from running dry, it must be installed below a certain mark with a small margin.

For each pump, the dynamic indicator is different, it depends on how efficient the pump is. The value is also influenced by the section of the casing pipes. The larger it is, the slower the level will decrease.

The pumping device in relation to the bottom of the mine must be located at a distance of at least one meter. The minimum dynamic level for the water intake and the pump from the second pumping will be the sum of this value and the height of the device. When the distance from the pumping device to the bottom is less than half a meter, the device will capture sedimentary silt and sand, which will affect its service life and water purity. The liquid column above the pressure equipment should also be at least half a meter in order to reduce the risk of dry running.

When measuring, it must be borne in mind that during the period of intensive water consumption, the water column in the wellbore sinks. At the same time, liquid enters the hydraulic installation from the aquifer. For the values to be correct, it is necessary to wait about an hour with the pumping equipment running before measuring.

Water column and well flow rate

The smaller the difference between the level marks in the pumping process, the greater the flow rate when using pressure equipment.

Knowing the data of the levels and the productivity of the pressure head device, it is not difficult to calculate the flow rate.If we consider an example, then a pump capable of lifting a cube of liquid per hour gives an interlevel difference of five meters. If the water column is slightly more than 15 meters, then the actual flow rate will be equal to three cubic meters per hour or 200 liters per meter. Since it is not recommended to reduce the dynamic level by less than two-thirds of the total height of the water column, the operational flow rate will be about two cubic meters per hour.

If no fluid is being pumped out, the debit value will always be zero. This is due to the fact that the bottomhole head in the wellbore is made equal to the formation pressure. When these conditions are reached, the flow of liquid into the mine stops.

In order to control the height of the water column in the water intake source and turn off the electric motor of the pressure equipment if the indicator drops to a critical level, it is recommended to install a water level sensor, which will avoid dry operation.

How to determine the water level in a well

The first measurements are carried out after the arrangement of the hydraulic structure and the installation of pressure equipment. But then additional measurements are taken to control the well flow rate. It is recommended to check the level indicators during increased water withdrawal and in the absence of precipitation for at least several days, when the liquid in the well installation is at a minimum. This is usually celebrated in the summer season, when a lot of water is spent on irrigating plantings.

They find out the level indicators in different ways, depending on the measuring device called a level gauge or USK.

More often simple cable models and electric level gauges are used to measure the water level in wells. If the hydraulic structure is shallow, you can use an apparatus assembled by yourself.

The simplest are cable level gauges. Structurally, they are a reel with a wound measuring cable. The principle of operation of the level gauge is as follows - it is lowered into the mine to the water mirror, then the required level is determined by the marks on the cable. But there are devices with more complex designs.

Lot meters

Structurally, they are similar to a winch, but at the end of the cable there is a lot-clapper. As soon as this element comes into contact with the surface of the water, a pop will be heard, which is a signal for the measurement.

Lot meters are simple in design and do not require a power source. But when making accurate measurements, extraneous sounds interfere, especially if the water in the mine is at great depth. The optimal location of the water table for measurements with a lot apparatus is up to one hundred meters from the ground level.

Electrical contact devices

Such devices require an electrical connection. To provide electricity, the contact is connected to the conductive pipe through a cord and clamp.

They use electric level gauges as follows:

- The device is held by the handle and the brake lever is turned on.

- The loaded electrode is lowered into the borehole.

- Upon contact with water, a characteristic sound is heard, and an indicator lamp flashes on the coil.

- Readings are taken according to the markings on the cable.

Special hooks are installed on the coil of the device so that it can be fixed at the top of the casing. This protects the cable from possible damage.

If a thermometer is installed on the electrical contact device, it will be able to detect not only level values, but also water temperature. The coil is equipped with a display showing temperature readings.

Wavemeters

A sound wave is used to establish the water level in the well. The wave meter creates it with a pneumatic shot from a pneumatic firecracker. Further, the time of sound propagation from the wellhead to the water surface is recorded. For this, a device is used that converts time into distance.

Pneumatic shot allows keeping an increased pressure in the annulus, which reduces the error in determining the level indicators.

Ultrasonic devices

The most expensive instrument among the meters. To receive data, the echo sounder is connected to a computer device. Devices of this type are not immersed in a mine, they work as follows:

- The ultrasonic sensor is located at the wellhead.

- He sends signals down.

- The data is shown on the display.

The ultrasonic level gauge may only be used after training. In addition to detecting the water level, the device can be used to find pipe damage and determine their severity.

The easiest way is if the hydraulic engineering device was created by professionals. Specialists engaged in punching borehole shafts issue a passport for the well, where they indicate the result of calculations of levels and flow rates. In addition to these readings, the document contains data on the dimensions and material of the casing pipes and advice on the use of suitable pressure equipment.

In the absence of a passport, measurements will have to be carried out independently. In this case, it is necessary to purchase a pressure device with a capacity four times lower than the flow rate.