In order for the water supply system in a private house to work correctly, a check valve for the pump is required. If it is not installed or is broken, the pumping station does not function correctly. The water flow enters the consumption point with a delay and, with a weak draft of the pressure equipment, it will completely disappear. The presence of a non-return valve contributes to the immediate receipt of water as soon as the tap is opened.

Definition and purpose of a check valve

A direct-acting protective device blocks the return flow of liquid in the water supply system. It works automatically.

Return devices are necessary elements of an autonomous water supply network. Their main function is to protect pipelines and pressure devices in case of emergencies.

Depending on the type of element, it is installed in a vertical or horizontal position. Installation is carried out in strict accordance with the direction of movement of the water flow.

Valve classification

By design features, the devices are as follows:

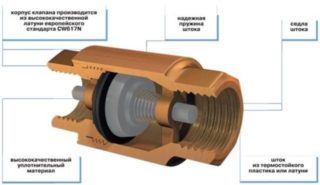

- With a lifting type locking element. The valve is equipped with an up or down shutter blocking the water flow. When liquid enters, the shut-off part goes up and lets it through. When the pressure drops, the shutter is directed downward and blocks the return flow of the water jet. The movement of the mechanism takes place with the help of a spring.

- With a ball valve. Under the pressure, the ball moves and water flows through the system. After the pressure has dropped, the shut-off element returns to its place.

- With disc-shaped constipation. The disc blocks the return flow thanks to the spring device.

- With two shutters. They fold under pressure, and when the pressure decreases, they return back.

In everyday life, equipment with a lifting type mechanism is most often used. It can be easily repaired by replacing the spring.

The fixtures are made from a variety of materials. Brass elements do not corrode, are easy to maintain, and can be installed on all types of pipes. Cast iron blocking devices are not used very often. This material rusts, deposits settle on it rather quickly. These valves are only suitable for wide lines.

Stainless steel cases are the most reliable, but also the most expensive. Steel valves do not rust and are not affected by aggressive media, and deposits do not accumulate inside them.

Most of the elements are mounted using a sleeve connection. To do this, you need two threaded adapters, selected according to the section of the pipeline system. Bolted flange connections can also be used. This type of fastening is used for small devices when there is not enough space on the pipes for other fastening. They are usually equipped with valves made of large section cast iron.

The combination of these parameters, as well as the brand, determines the price of the product. The average cost is 700 rubles.

Installation steps

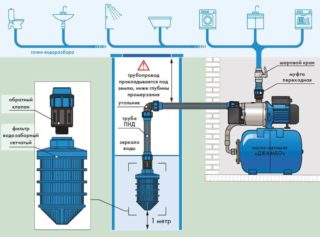

Depending on the location, the shut-off valves are divided into bottom and pipeline.The first type of valves prevents the return of water flow raised from a well or an Abyssinian well when the station is shut down. The second protects against a decrease in the pressure in the water supply network.

The valve element is connected to an autonomous system immediately after the pump or in front of it. The first option is chosen if the pumping device is capable of starting with the valve closed. The discharge element can be equipped with a pre-assembled transition fitting for the suction pipe. If it is missing, you need to buy this part and put it on the pump.

Self-assembly of a non-return valve is performed in the following order:

- They select a model and check the performance. To do this, blow through the mouth from both sides. On one side, the shutter opens, on the other, it holds air.

- Shows the correct direction of installation according to the arrow on the body.

- The valve element is screwed onto the thread, having previously wound the sealant.

- Tighten the locking equipment with a gas wrench. The main thing is not to overdo it - the case can burst.

If it is possible to drain from the system or the pump can operate in reverse mode, it is impossible to install the valve part after the hydraulic accumulator - it will block the outflow of fluid.

The bottom valve is installed together with a mesh filter that cleans the water from sand and protects the inside of the device from wear. Devices equipped with a spring element and a lifting lock are the least contaminated. In order to properly install the non-return bottom valve with a strainer to the pumping station, it is better to immediately purchase the version with a strainer. There are products with a removable filter element for easy replacement.

The easiest way to mount the valve is with a wafer connection. But in private houses, devices with a threaded sleeve connection are mainly used due to their low cost.

It is necessary to check the operation of the non-return valve for the pumping station and after installation. To do this, you need to turn the lever in the right direction. The result will be water flow.

Possible installation errors

Common mistakes when arranging a non-return valve:

- flow direction is not taken into account;

- connections are poorly sealed, which can lead to leaks when the valve is closed;

- the cross-section of the device is too large, so it knocks during operation;

- the valve is too close to the pump, which causes rattling;

- used a lot of plumbing flax when winding the thread - the coupling may split.

Sometimes they forget to remove the bore plug or the bolt lock.

Expert advice

For the water supply network, it is better to select valves made of brass or stainless steel, since they are not afraid of rust and have a long service life.

You also need to consider:

- The location of the device in sewage pipelines without a ladder is chosen in the area above the highest drainage point - not lower than 350 mm from the floor.

- In houses with independent heating, the valve should be installed on the return line before connecting to the heating system.

- In high-rise buildings, where a separate water supply network is mounted, the valves are mounted after the water meter.

The wafer check valve is installed after the flanges have been welded to the pipeline. It is extremely important to observe the alignment of the pipes at the point of installation of the device, since the misalignment will break the tightness of the connection.

Installation of check valves allows you to get rid of many problems that lie in wait for the owners of an independent water supply system. The locking elements will not only ensure the functionality of the network, but also save money on repairs.