Well construction involves the use of a productive pump. With its help, it is possible to raise water from great depths, constantly maintain the optimal pressure in the pipeline. The use of submersible vibration pumps for wells is widespread among craftsmen. Their technical characteristics are optimal for any source.

Purpose and scope of vibration borehole pumps

With the help of a vibrating submersible pump, a liquid medium is lifted from a depth of 20-30 meters and successfully transported along a highway. Such units are used in the following cases:

- lifting water from a well, well;

- pumping a freshly drilled source;

- drainage of a well, a well with a small flow rate for inspecting the bottom and cleaning it;

- filling the storage tanks with water and returning liquid from them (watering, car washing, etc.);

- intake of liquid from natural sources at the dacha (pond, lake, river) for irrigation of orchards;

- drainage of flooded premises (basement, cellar).

With proper operation, a submersible vibration pump can last from 10 years.

Advantages and disadvantages

The vibratory unit has both advantages and disadvantages. The first include:

- relatively reasonable price;

- a wide range of models - you can choose devices from a domestic or foreign manufacturer;

- low noise level;

- optimal performance;

- the ability to raise water from great depths;

- ease of installation, connection.

The disadvantages of vibrating borehole pumps include:

- Lack of thermal protection for some models. Without it, on dry running, the unit will work no more than 10 seconds. After that, the winding will burn out.

- Regular loosening of threaded connections when exposed to vibration. The issue is solved by replacing the nuts with self-locking ones.

- Bolt susceptibility to corrosion. Even the zinc coating wears off over time, which leads to the formation of rust on the fasteners.

- Wear of rubber elements under the influence of abrasive sand particles in the water, especially if the well is made on limestone or sandy formation.

- Sensitivity to voltage drops in the network. For example, if the current decreases by only 15%, the pump performance drops by almost half.

The vibrating pump destroys the walls of the concrete casing over time. The problem can be solved with the help of a tight rubber ring, which is put on the sleeve of the device in its widest part during installation.

Types, principle of operation and device

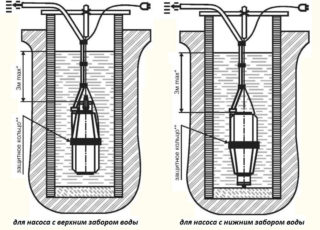

- With upper water intake. The inlet pipe is located at the top. The models are distinguished by a long service life due to the fact that small debris at the bottom of the source (sand, clay) does not fall into the device chamber. Additionally, the water entering through the upper part-tube cools the electrical components of the unit. But the disadvantage of a pump with an upper intake of liquid is that when the water mirror in the well falls, the device is idling. It is advisable to use devices with an upper intake for sources with intensely dirty water and at a constant flow rate.

- With a bottom water intake. Models are good in that they can supply liquid from almost the bottom of the source. Therefore, bottom suction pumps are especially good for wells with unstable flow rates. But here it is worth keeping an eye on the level of contamination of the bottom.If the source is very sandy, you cannot do without a coarse filter. Otherwise, debris will quickly damage the pump.

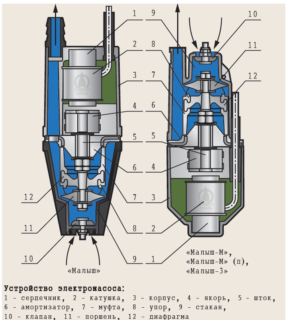

All vibration model models are structured almost the same. The only difference is in the location of the inlet pipe. The main working elements of the vibration device:

- working chambers;

- membrane;

- vibration device.

Downhole units work as follows:

- When the pump is turned on, an electric current is supplied to the winding. It creates a magnetic field that attracts the vibrating device to itself.

- The diaphragm (membrane) bends towards the storage chamber and draws water into it. This is due to the generated vacuum in the suction chamber.

- As soon as it fills up, the pressure rises again and the water overflows with the help of a piston, which pushes it upwards. It goes into the pipes and further into the main line.

Cycles of magnetization / demagnetization are repeated constantly (more than 100 times / sec.). This ensures the continuous operation of the vibration pump.

How to choose a vibration pump

The purchase of a downhole vibration device is always based on the following criteria:

- Pump performance. Should not be higher than the flow rate of the well, otherwise it will drain.

- The power of the device.

- Desired head of the device. Calculated by the distance from the well to the farthest plumbing point of the house.

- Casing diameter and source depth.

It is advisable to mount a submersible pump with a bottom intake at least one meter from the bottom of the well.

Installation principles, connections

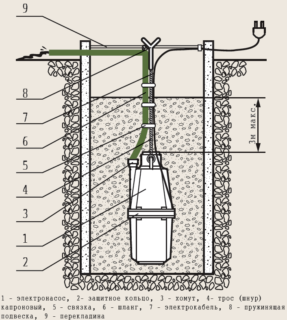

To install the vibration unit, you need to prepare:

- Water supply hoses (intake and supply). Their cross section must be at least 18 mm.

- Fittings for connecting hoses to the pump.

- Coarse filter plus check valve.

- Safety rope. It is advisable to take not steel, but dense nylon.

- Rubber ring on the sleeve of the device.

- Clamps or at least construction tape.

The assembly and installation of the system is performed as follows:

- On the one hand, a water intake hose is attached to the inlet pipe using fittings. At its end, a coarse filter is immediately mounted.

- The second part of the hose (supply) is mounted to the outlet. A check valve must be installed on it.

- A safety cord is attached to the pump eyes. Thus, three components must extend from the unit - a cable, a water supply hose, an electric cable. To avoid them sagging in the well, it is better to tighten all three elements with clamps or tape. Strong tension should be avoided for each of them. The pitch of the clamps is 50-70 cm. It is better to make the first connection 20 cm from the pump sleeve.

- A dense rubber ring is put on the body of the unit.

- The pump is lowered to a predetermined depth.

- A strap can be laid across the casing, to which a safety cable will be fixed.

- Connect the device to the network.

For class 1 unit protection, the socket must be grounded.

Features of operation and maintenance

For the correct operation of a submersible vibration pump, you must adhere to the following recommendations:

- it is forbidden to use the equipment with a damaged electrical cable;

- if the pump is running, the water supply must not be shut off;

- permissible continuous operation of the equipment - no more than 2 hours;

- if the unit is not used in winter, it is lifted out of the well, dried, lubricated with fasteners and stored in a dry place.

To use the device in winter, a small hole of 1.5 cm is made in the hose next to its body. It helps to protect the pump from freezing and provides a free outflow of water. For the summer, the hole can be closed with electrical tape.