The borehole screw or screw pump is designed to solve the problem of water supply in small private and country houses, small agricultural land. The advantage of the device is the ability to work in the presence of solid impurities in the water, even at a high concentration. Therefore, for Abyssinian wells and weak wells, screw water pumps are the most optimal option.

Purpose and scope

Small-sized domestic water units are made of one common shaft. In industry, multi-shaft is most often used. During production, special attention is paid to the sealing of the working surfaces. Graphite and ceramics are used as sealants.

Screw pumps have a wide range of applications in the agricultural and other industries:

- transportation of food products during their packaging;

- pumping oil and its derivatives;

- natural gas production;

- pumping out water during coal mining;

- transportation of oily liquids.

Screw pumps are especially widely used in the domestic sphere. They are installed in private backyards for the extraction of water from wells.

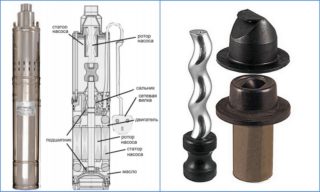

Types, principle of operation and device

To prevent water from running out of the tap with admixtures of sand, silt and algae, a coarse filter is additionally installed on the inlet pipes.

Unlike centrifugal designs, screw designs are compact in size, but at the same time create high pressure. The diameter of the body is reduced, since the structure is, roughly speaking, one shaft.

The rotor is a rotating screw, the stator is the inner surface of the housing. As a rule, the screw is made of high quality metal, and the working surface of the stator is made of plastic materials. When the rotor rotates, water is sucked into the inlet pipes and spirals to the outlet.

Criterias of choice

To acquire the right equipment, you should consider the basic selection criteria. Improperly selected equipment often fails, and also due to technical limitations is unable to fulfill all the tasks assigned to it.

When buying, it is important to pay attention to the following characteristics:

- Power and performance. It depends on this parameter whether the pump will be able to provide the water supply system in the required volume. If there was no previous experience, it is better to consult with employees of the utility company or water utility.

- Manufacturing firm. It is better to refrain from buying a pump of dubious quality from an unknown manufacturer. Reliable imported pumps are expensive.However, do not underestimate Russian products. The popularity of the pumping stations of the Kharkov plant Promelectro, as well as the Russian aggregates Aquarius, is growing.

- Well depth. This indicator is perhaps the most significant when choosing equipment for water supply. The deeper the liquid is, the more powerful the equipment is required. In addition, it is important to consider the distance from the distributor inlet to the water intake. 10 m of the horizontal section is equal to 1 m of rise from the depths.

- The cost varies widely and depends on the features of the configuration of the model. It is not recommended to save money when carrying out water supply and sewerage, since cheap pumps of dubious quality quickly fail, and their repair inevitably requires additional costs.

Before purchasing the equipment, you should carefully read the attached documentation and warranty card. All technical parameters of the model are described in detail in the instruction manual.

Installation and connection, features of operation

- The pressure hose is connected to the screw pump with clamps.

- To lower the equipment to the required height, you need to attach a metal cable or a nylon cord to the body. The lower part of the body is equipped with a special lug.

- The equipment is immersed in the borehole and the upper part is attached to the beam to be installed on the surface above the borehole.

- An electric cable is connected to the control unit and a test run of the pumping station is carried out.

To extend the life of your equipment, it is important to familiarize yourself with the specifics of the operation. As a rule, they include the temperature of the working environment, the composition and concentration of solid particles in the liquid, the stability of the power supply. If the unit is not equipped with a filter for coarse cleaning of the liquid, you need to purchase and install it, this will prevent the formation of blockages.

Advantages and disadvantages of screw submersible pumps for wells

The advantageous features of screw pumps include:

- the ability to pump out liquids of different quality;

- high power and performance of the system, subject to all operating rules;

- the absence of loud sounds and extraneous noise during the operation of the unit;

- ease of maintenance.

The ability to work with different liquid media is one of the most important factors when choosing a unit. Screw water pumps are not sensitive to solids in water, unlike centrifugal and hand pumps. They handle viscous and highly contaminated fluids without compromising performance.

Another significant advantage of the equipment is its compact size. As a rule, these are submersible pumps, the dimensions of which do not exceed the diameter of the well. The body most often has a cylindrical shape, rarely exceeding 12-15 cm in diameter.

Power and productivity depend on the rotational speed of the auger: the more revolutions, the higher the productivity. Standard models for domestic use are capable of maintaining the water level in the system at around 1500-2000 l / h.

Despite the large number of advantages, the equipment also has disadvantages:

- high price;

- lack of opportunity to work "idle";

- fixed amount of work.

By giving preference to this type of pumping equipment, the buyer will pay several hundred dollars. If you want to save money, you can pay attention to domestic manufacturers who have earned the trust of consumers. Belamos, Vodomet, Malysh - pumps adapted to Russian conditions.

Screw pumps have no analogues when pumping drinking water with a high concentration of harmful impurities from a well.