Do-it-yourself plumbing in a private house can be made from a centralized network or from a well, a well. The principles of arrangement, the main nodes of the highway do not actually differ.

Types and arrangement of water supply systems in a private house

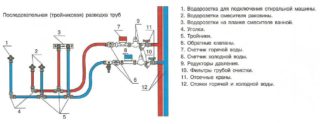

Series or tee connection

A water supply scheme of this type in a private house implies that the tap, shower and other points are connected one after the other.

The advantages of this solution:

- ease of installation - no special knowledge is required when connecting additional elements;

- low cost - half as many pipe sections are used;

- compactness - tees are mounted directly near the taps.

However, there are also disadvantages. If all consumers are turned on at the same time, a significant drop in the pressure in the water supply network occurs. Connecting a new user is problematic. You will need to insert another tee.

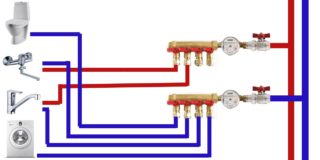

Collector or parallel connection

It is the installation of a splitter or two - for hot and cold water supply, to which branches are connected to each consumer. To make an eyeliner of such a plan, a larger footage of pipes is needed, but at the same time, its principle of operation helps to maintain a constant pressure.

Collector system advantages:

- convenience - all nodal points are in one place;

- reliability - one pipe is supplied to each consumer, which significantly reduces the possibility of leaks;

- pressure stability - the manifold evenly distributes the pressure between all users, so even if you open all the taps at once, the pressure in the system will not drop.

The disadvantages include the high cost due to the increased consumption of materials and the need to allocate space for the installation and connection of collectors.

Water supply principle

The installation of the water supply system is carried out by a dead-end, circulation or combined method. "Deaf" branches, ending with a plug, are more economical, but there are inconveniences with hot water supply. When you open the tap, you need to wait a while until the water reaches a dead end.

Circulating branches of a closed type are more practical and convenient, but to implement such a project, you will need not only more pipe sections, but also a special pump.

The best option is the combined type - dead-end distribution of cold water supply is combined with a hot circulation circuit.

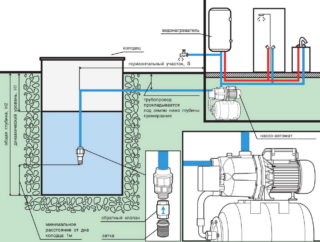

Automatic water supply equipment

The choice of the method of laying and assembling the water supply network of a country house begins with an assessment of the type of water intake structure, its depth and functionality.

The automated system consists of the following parts:

- a pump or a finished pumping station;

- filtration system for water purification;

- tanks for accumulation and regulation;

- pipe lines inside and outside;

- devices for automatic regulation.

Equipment of such a plan is mounted for water supply of a large country cottage.In a tiny private house and in the country, there are enough pipes and a pump.

Design and calculations

In order not to engage in alteration of the trunk nodes, it will be necessary to draw up the correct wiring diagram. It should include all water intake points, through-type elements and valves. The drawing indicates the cross-section of the pipes, the location of the water heater and the pumping unit.

There it is also necessary to note the drainage lines: where the drains will go - to the central system or a cesspool, a septic tank, a deep cleaning station.

When choosing pipe sections, connecting elements, it is necessary to calculate the throughput of the pipes depending on the cross-section, the length of the line and the pressure. This can be done using tables, formulas and computer programs.

DIY installation steps

To carry out the work, complex equipment is not required, all the tools are in home workshops: a pipe cutter and a shovel for outdoor work, as well as press pliers for crimping bushings that are put on the pipe. If the connection is going to be done by hot welding, you will need a pipe soldering machine and nozzles for it. From materials in addition to pipes and fittings, fum tape, sealant, gaskets can be useful.

The installation of an external network is carried out as follows:

- A narrow ditch is dug up to the freezing level plus 0.5 meters.

- At the bottom, a pillow is made of compacted quarry or river sand.

- Equalize the bottom with a slope of 20-30 mm per meter.

- Insulate the part of the pipeline laid above the freezing level before entering the foundation base.

- The pipe is installed and covered with clean sand without clay inclusions.

Where the line needs to be fixed to the wall, special clips are used. Rigid fixation is not applied to polypropylene pipes - it is necessary that they can easily move when expanding under the influence of temperature extremes. Clips are installed with a step of 1–2 m between them.

If you need to fix a pipe section of a large section or mass, for reliability, you should use clamps.

When laying outside the pipe through the walls and ceiling, they are passed in sleeves - covers made of non-combustible material, which are filled with a sealant, for example, mineral wool. This is necessary to reduce noise when passing through the liquid. It is allowed to cut the sleeve at the level of the walls and ceiling, but it should protrude 3 cm above the level of the finished floor.

Do-it-yourself installation of the inside of the system:

- They make markings for the passage of the future plumbing system - on the walls, in the screed or under the ceiling.

- They beat the grooves in the walls or hide the pipes in the floor screed. They are fixed on the ceiling by means of clips of the required diameter. If the pipeline is installed on the floor, it should run at a distance of no more than 15 cm from the wall and at least 20 cm from the future furniture.

- Pipe sections are connected by means of shaped parts or by welding.

- Connect shut-off valves and a water heating installation, a booster pump, plumbing fixtures, installing gaskets, where necessary.

Leave approximately 15–20 mm of empty space between the wall and the piping. In the future, this will facilitate the repair of the water main in case of an emergency or a leak. It is worth installing its own shut-off valve for each branch from the riser to the plumbing fixtures. So in the event of an accident, there is no need to shut down the entire system.

Basic mistakes when installing the network

You need to know about frequent mistakes in order to eliminate these problems in the process of self-assembly of the network:

- Pipes with hot water, hidden in the walls or under the floor screed, forget to insulate.

- They strive to "stick" all pipe sections through one hole in the wall or overlap.

- The compression nuts of the fitting elements are not fully tightened.

- Do not install shut-off valves in front of each plumbing fixture.

- Do not put shut-off taps separately for each riser and each bathroom, if there are two or more of them.

- Do not observe the slopes of the pipe lines.

Often during installation, the end parts of the pipes are not plugged, which is why debris gets there.

All these shortcomings lead to the fact that the system functions poorly, leaks occur. Having thought over all the nuances in advance, it is easy to avoid problems and assemble a working network on your own.