Pipeline fittings are plumbing equipment designed to regulate the supply of a working medium through water supply networks. This type of mechanism includes any valves and taps installed on communications.

Definition and purpose of valves for water supply

Stop valves differ from control valves in that they are designed to completely stop the movement of the carrier, and not to control the throughput of the pipeline. Such devices have a number of common features:

- wide range of working pressure and temperature;

- anti-corrosion coating that extends the life of the metal;

- required bandwidth.

Plumbing fittings are made of plastic, brass, bronze, cast iron and steel.

Principle of operation

The shut-off valve works according to a simple principle - during its twisting, the cross-sectional area of the body passage opening changes, as a result of which the movement of the liquid stops. In more detail, the operation of the device can be described using the example of a pipeline valve:

- The operator turns the flywheel.

- Thanks to the threaded connection, the stem starts to move.

- The stem pushes the bolt. The process is controlled with a guide.

- The shutter closes the opening of the body, preventing the movement of liquid.

A shut-off device should not be used to regulate the flow. Prolonged exposure to water on metal elements leads to their grinding and loss of efficiency to completely block the communication.

Types and device of shut-off valves

Depending on the features of the application, the following types of fittings are distinguished:

- Locking. This class of products is the most numerous - it makes up ¾ of all devices used. Used to completely shut off the flow of the carrier in the line and start it if necessary. Shut-off products include gate valves, taps and valves. They are used to regulate the movement of various media - gas, steam, water.

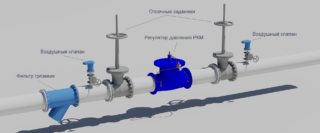

- Regulatory. Devices of this type of shut-off valves of water supply systems have valves and are called regulators of the level of liquid, pressure, medium. They move due to the work of the electric drive. One of the common names for such models is throttling valves.

- Safety. Thanks to these devices, communications for various purposes are protected from overpressure in excess of permissible values. If this indicator becomes more than the norm, a partial discharge of the working environment occurs. Safety valves include bursting discs, bypass valves, impulse devices.

- Protective. The main value of such mechanisms is to prevent accidents and breakdowns when the parameters of technological processes are unacceptable for the line. In addition, the mechanism prevents the working medium from flowing in the opposite direction. Safety valves include shut-off and non-return valves.

- Distribution and mixing. It has another name - multi-pass. Such devices include control valves and three-way valves.Products are used for mixing media or distributing work streams in several directions.

- Control. Designed to monitor and control the level of liquid in boilers and vessels.

- Phase separation. Used to separate working environments in different states. Such devices include condensate drains and oil separators.

Shut-off valves can only be in two positions - "fully open" or "fully closed". Depending on the type of valve gate valves are classified into wedge, disc, parallel. When creating irrigation systems, stop valves for water pipes with a timer are used.

By the method of connection, the devices are divided in accordance with the following classification:

- Flanged. This type of fittings is presented in round, rectangular and triangular models. Square devices are designed for environments with limited pressure indicators - not higher than 2 atmospheres. The round shape is more preferable - a minimum of resources is spent on its production, and in terms of reliability it surpasses other types.

- Flangeless. The range of offered products of this type is quite extensive in the ways of its connection to pipelines, branch pipes of tanks and vessels. Models of this group can be trunnion, choke, welded and coupling.

Stop valves are installed on HDPE, metal-plastic, polypropylene and stainless steel lines.

Main selection criteria

When choosing plumbing fittings, several criteria should be considered:

- Appointment. It can be used for outdoor and indoor networks.

- Material. If you need to use valves or regulators in an aggressive environment, it is better to choose a ceramic product. This material is less susceptible to degradation than plastic and metal.

- Maintainability.

- Appearance. When choosing fittings that are planned to be placed in plain sight, it is worth considering the style of the interior.

When choosing a brand, it is better to rely on trusted manufacturers. These include the Valtek company, which sells engineering plumbing in Russia and the CIS countries.

Installation features

When choosing plumbing fittings for an apartment, you should make sure that it matches the pipeline according to the following indicators:

- the same sectional shape;

- the same diameter;

- the possibility of a reliable connection of the shut-off device and the pipeline: identical flanges, matching threads.

Basic rules for installing plumbing fittings:

- Any work must be performed only on the disconnected section of the highway. It is important to make sure that there is no working fluid left in it, and that the temperature and pressure are correct. Air vents and drains must be open. Warning signs are posted on each side of the fittings along the pipeline line.

- The pre-assembly preparation of the connecting elements of the locking structures involves cleaning them from dirt and traces of corrosion.

- It is necessary to install locking or regulating mechanisms only on straight and level sections of the highway. It is forbidden to mount it on bends, as this can reduce the tightness of the water supply system.

- For heavy elements of gates and valves, support structures should be provided.

- The fasteners must be tightened with special tools. To prevent the flanges from skewing, they must be tightened first from one edge, then from the opposite.

- Welding is carried out only on valves with an open valve.

When installing shut-off elements, it is important to pay attention to the correspondence of the position of the device to the direction of the medium flow. It is indicated on the bodies of taps, valves and gate valves. For pipelines with the possibility of two-way movement of liquid or steam under high pressure, 2 stop valves are installed, designed for different directions of flow.

The cost of valves starts from 100 rubles and can reach 200 thousand rubles.The price depends on the size, material of manufacture, features of the device operation.