On the building materials market, the water pipe with a diameter of 25 mm is presented in two types: steel and plastic. The latter type is divided into groups based on the polymer from which tubular products are made. The main purpose of pipes of this diameter is the organization of cold and hot water supply networks, as well as heating systems.

Steel tubes

The selection criteria depend mainly on the material from which the pipe sections are made. Therefore, it is necessary to conduct a comparative analysis of all plumbing products on the market.

On the market, steel pipes with a diameter of 25 mm are presented in two types, which differ from each other in the production method:

- Cold-deformed. These are products belonging to the "seamless" category. They are produced on a rolling mill with further cold calibration.

- Electrowelded, in which there is a seam.

The latter are divided into two groups: with a straight seam and a spiral seam. In the assortment with a spiral seam, pipes with a diameter of 25 mm are not. The minimum diameter here is 159 mm. If cold-worked can be installed in water supply networks with high pressure, then electrowelded only in systems with moderate pressure.

Steel pipes differ from plastic ones in that they have a minimum coefficient of linear expansion, they can easily withstand quite serious mechanical loads, changes in humidity and temperature. They will not be damaged by rodents. The method of connecting pipes to each other and to fittings is electric welding.

A separate category is water and gas pipes (VGP). They are considered the most demanded in the steel pipe category. Gas networks in accordance with GOSTs can be carried out only from steel pipe products. Manufacturers offer galvanized models that guarantee a long service life due to an additionally applied protective layer.

Plastic pipes with a diameter of 25 mm

Plastic pipes with a diameter of 25 mm are presented in a small model range. They differ from each other in the material from which they are made. Hence the technical and operational characteristics that are different from each other.

Propylene products belong to the class of thermoplastic and durable. Their distinctive characteristics:

- withstand short-term exposure to temperatures of + 100C;

- do not change their size and technical characteristics when interacting with chemically active substances (alkalis, acids and salts);

- withstand high mechanical loads (pipes of this type can be laid in an open way).

Manufacturers offer two types of performance:

- ordinary;

- reinforced.

The first type is purely plastic pipes. They have their own classification, which is based on the pressure of the water flowing through the water supply network. The marking has an alphabetic designation - "PN", and a numerical designation of pressure.

Products of brands PN10 or 16 are recommended for use in plumbing systems, and PN20 or 25 in heating systems.

The second type is two layers of polymer, between which a reinforcing layer is laid. Usually it is aluminum foil or aluminum wire mesh. Manufacturers use fiberglass or composite mesh.

On the market, polypropylene pipes are presented in two types: for cold and hot water. A blue line is drawn on the outer plane of the former, and a red line on the latter.

Prices for polypropylene plastic water pipes with a diameter of 25 mm depend on the class of the product. The PN10 brand costs 22 rubles. based on one running meter.PN16 price - 26 rubles. The cost of PN16 reinforced version costs 62 rubles.

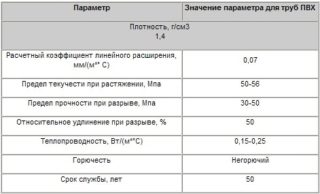

Polyvinyl chloride (PVC) pipe sections are not widely used in water supply systems. The reason is the complexity of connecting the elements of the water supply network.

To connect PVC pipes, special fittings are used, which are fastened together with threads. The second joint technology is cold welding, which uses a special adhesive.

We must pay tribute to this type of pipe material for its high strength and neutrality to all chemicals.

The price of a PVC water pipe with a diameter of 25 mm is 220-250 rubles / r.m.

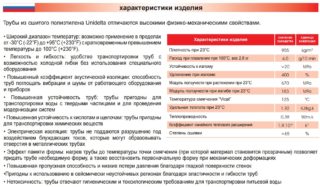

Manufacturers offer two varieties polyethylene pipes: low and high pressure. The second ones with a diameter of 25 mm are not produced, because these products have a reduced strength due to the low density of the plastic itself.

The former, on the contrary, have a high density and strength. At the same time, HDPE pipes are very flexible. When it is necessary to conduct a branch or branch, they are laid, bending to the required bending radius - installation is carried out without the use of connecting fittings.

HDPE pipes are produced only in black. Some companies apply a blue line to the surface, thereby indicating that these products can only be used when forming a cold water supply. Under the influence of high temperatures, polyethylene softens, therefore it is not used in a hot water supply system or in heating networks.

According to GOST, polyethylene pipes with a diameter of 25 mm are produced with a wall thickness of 2 to 2.3 mm. The weight of one running meter is 0.12-0.16 kg. The pipes can withstand pressures up to 16 MPa.

High frost resistance can be added to the advantages of low-pressure polyethylene pipes, therefore, temporary water supply networks are built from them at dachas, which are laid in an open way. They are not canned for the winter. There are two ways to connect the elements of the water supply system to each other:

- using couplings;

- by welding.

Experts give preference to the first as the simplest.

Prices per meter of HDPE water pipe with a diameter of 25 mm, depending on the wall thickness, vary from 20 to 25 rubles per running meter.

Products from cross-linked polyethylene have increased flexibility, so they are sold in coils. The uniqueness of this type of pipe lies in the fact that it can be used for laying not only cold water supply. It easily tolerates high temperatures, therefore it is used in the organization of hot water supply and in heating systems. The cross-linked polyethylene material was especially popular when forming a system of underfloor heating.

The pipes can withstand temperatures up to + 95C, pressure up to 16 MPa. Bend at a radius of 10 cm. The guaranteed service life is 50 years. Connection method - ferrules or press fittings. Price - within 100 rubles / r.m.

Reinforced plastic pipes are classified as reinforced. They include aluminum foil. It is located in the middle of the wall of the product and is attached to two layers of plastic with a special adhesive, which is applied using hot technology. Metal-plastic is a flexible material, so pipes are sold in coils.

Compared to a cross-linked polyethylene pipe, in which bending can be carried out under a radius of 10 cm, for metal-plastic this parameter is 6 cm.The other characteristics are almost the same:

- the maximum temperature that a metal-plastic pipe can withstand is + 95C;

- pressure - 10 MPa;

- slight linear expansion, which provides a reinforcing layer - 0.81%;

- service life - 50 years;

- the price is about 100 rubles per meter.

Reinforced-plastic pipe products are rarely used in the formation of water supply networks, because they are more expensive than other models. In underfloor heating systems, they guarantee efficient operation and ensure ease of installation.