When carrying out plumbing work within a private house, craftsmen mainly use plastic pipes with a size (section) of 32 mm. They differ in a number of positive characteristics. At the same time, they have an acceptable cost.

Purpose of water pipes with a diameter of 32 mm

Basically, these elements are used for laying the following systems:

- cold and hot water supply;

- transportation of non-aggressive substances (for steel);

- air supply in air conditioning systems;

- heating of a private house plus a warm floor system (for large objects);

- compressed air supply;

- transportation of gaseous media;

- irrigation and drainage systems of private households;

- product pipelines in the food industry (especially often they use a polyethylene blue water pipe with a diameter of 32 mm);

- as a protective outer screen for cable routing.

Pipes with a cross section of 32 mm are used when installing a water supply system if the total length of the system exceeds 30 m.

Specifications

Water pipes with DN 32 mm are made from different materials. Their technical characteristics depend on this. However, there are a number of unchanged parameters for all types of tubes with the named diameter:

- inner section - 32 mm;

- outer diameter - from 42 to 42.4 mm (in accordance with GOST or European standard);

- wall thickness - from 2 to 2.6 mm;

- throughput - 50 l / min;

- the length of one unit is from 4 to 15 m (depending on the material of manufacture);

- service life - 30 years (steel), from 50 years (polymers).

The correct choice of tubes for their cross-section allows you to avoid water hammer in the system, as well as turbulence and increased noise.

Manufacturing materials

Tubes in different designs are presented on the market. The master selects the product according to the type of the mounted system.

Steel

Metal pipes are used in places where there is a high risk of mechanical impact on the communication. Steel is a durable material, but it has a number of disadvantages:

- Corrosive tendency. The situation can be saved by galvanizing. But if the protective layer is damaged, rust cannot be avoided over time, especially if aggressive media are moving along the highway.

- Labor-intensive installation of the line. For the device of a steel pipeline, welding must be used.

- Silting up of the highway over time. Steel pipes tend to overgrow from the inside with debris, polyps. This reduces the internal lumen of the line.

Steel has an impressive mass, so it is not easy to transport and stack such elements alone.

Polypropylene

One of the most common materials for the production of water pipes is polypropylene. For each section, you can select products for the nominal pressure in the system. Such data are marked with letters PN. For example, if the product has a PN10 value, then the tube can be used for communication with a working pressure of 10 atmospheres. Polypropylene has the following advantages:

- inertness to any, even aggressive environments;

- good resistance to linear tension;

- the ability to work with high and low temperatures;

- smooth inner surface;

- light weight;

- ease of installation;

- reasonable price.

Polypropylene is afraid of ultraviolet radiation, so pipes are laid either inside the building or in the ground.

Pvc

PVC water pipes with a diameter of 32 mm can be used in systems with temperatures up to +90 degrees. At the same time, the permissible range of operating pressure in the line for these products is 6-46 atm. Among the advantages of PVC are:

- Fire resistance. Due to this quality, PVC tubes are popular when installing a protective cover for cabling.

- Light weight.

- Smooth inner wall, allowing media to move easily along the highway to their destination.

Installation of PVC pipes can be mastered even by a novice master.

Metal-plastic

This type of tube has a multilayer structure consisting of a reinforcing foil layer and a polymer. Each one is firmly welded / glued. As a result, metal-plastic has a number of features:

- inertness to corrosion;

- the possibility of using products at sub-zero temperatures;

- stability of the working pressure in the line due to the ideal smoothness of the inner walls;

- lack of strong polymer expansion under the influence of high temperatures;

- plasticity of tubes (bend easily, which makes it possible to mount communication without a large number of fittings);

- inertness to aggressive environments;

- low thermal conductivity;

- lack of conduction of stray currents;

- external aesthetics and environmental safety.

More often, Rehau metal-plastic tubes are used for the installation of heating systems or underfloor heating.

Polyethylene

This material can be further divided into categories:

- HDPE (low pressure polyethylene).

- LDPE (high pressure polyethylene);

- sewn PET.

Since all types of polyethylene tubes (except for sewn ones) do not react well to high temperatures, they are used for cold water supply or sewer. Polyethylene has the following features:

- resistance to aggressive environments;

- excellent dielectricity;

- maintaining healthy sanitary indicators of drinking water;

- frost resistance and moderate heat resistance due to the ability to linear expansion.

PET pipes are easy to install and have an acceptable cost.

Criterias of choice

The choice of pipes with a cross section of 32 mm is carried out according to the following criteria:

- Product material type. For the internal laying of the line, PVC, polypropylene, and metal-plastic are optimal. For outside - steel, PET.

- Purpose of pipes. Each product is marked with working pressure, optimal temperature indicators (hot & cold).

- Installation principle. Each master selects the type of pipes that he can handle independently.

- The presence of reinforcement (when installing heating and heating systems).

- Resistance of the material to temperature extremes (if it is supposed to transport media with different indicators).

Additionally, you need to pay attention to the service life, the cost of products and the manufacturer. Here everyone has their own requirements and capabilities.

Installation features

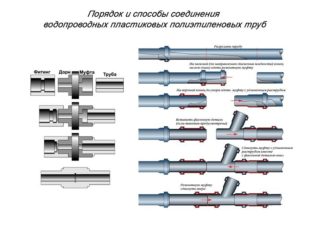

- Polyethylene pipes are joined using a welded joint, electrofusion or compression clamping fitting. The method is selected depending on the purpose of the line and on the skills of the master.

- Steel is joined by welding.

- Polypropylene pipes only require soldering using a special apparatus. Pipes and fittings are melted a little on the soldering iron nozzles and then joined. The cured polymer forms a strong bond.

- Reinforced plastic can be mounted using threaded or press fittings. A special tool is needed for the device of a metal-plastic line. In order not to spend money on an expensive purchase, you can rent it.

- PVC tubes are connected in the socket using special rubber cuffs.The sealing gasket is pre-treated with a sealant.

The wide part of the socket must face the direction of flow of the transported medium.

Cost of water pipes

Prices per meter of HDPE water pipe with a diameter of 32 mm and other products with the same section:

- steel - from 45 rubles;

- polypropylene - from 67 rubles;

- PVC gray (Ekoplast) - from 32 rubles;

- metal-plastic pipes - from 159 rubles;

- black HDPE pipes - from 14.8 rubles (while Djileks products cost from 76 rubles);

- LDPE pipes - from 20 rubles.

The cost for all types of products is quite acceptable, especially if a not very long highway is to be installed on a private site.