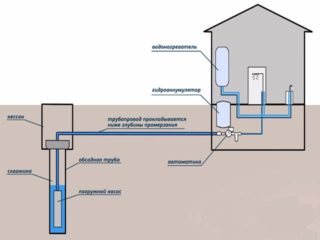

Regardless of what kind of building is being designed: residential, industrial or cultural-mass use, it must necessarily have water supply and sewerage systems. At the same time, both networks are designed at the same time, because the sewerage capacity will be calculated from the amount of water used. The water supply network itself is divided into two parts: internal and external water supply. The first part is the piping inside the building. The second is from the water intake source to the building. At the same time, external wiring is laid according to State standards.

Sources of water supply

In private housing construction, water supply sources can be: central water supply networks, open water bodies, dug wells or drilled wells. In addition to the first position, in all other cases, a water treatment system is organized, which includes a set of filtering elements that provide water purification.

The ideal option is a central water supply system, which provides houses with already purified water. But if the pipes of the system have been in operation for a long time, the corrosion processes of metals have also affected them. Therefore, the installed coarse filter will solve this problem.

Increasingly, in private housing construction, wells or wells are used for water intake. Because the water in these hydraulic structures is cleaner than in open reservoirs. But this does not in any way affect the design features and methods of laying an external water supply network.

Building regulations

First, they design a scheme for laying pipes for an external water supply system. It depends on the location of the house relative to the source of water intake, on the number of consumers, for example, if, in addition to the house, the water supply network is extended to the summer kitchen, bathhouse, garage, pool and other facilities. The more the latter, the more complex the wiring diagram.

It is also necessary to take into account the amount of fluid consumed. It depends on the number of people permanently living in the house. At the same time, it is taken into account that 200 liters of water or 0.2 m³ should be allocated for each person per day. It depends on this indicator what diameter of the pipe should be used, what capacity the pump should be installed. In this case, the pressure is necessarily determined at the latter - to what height the pumping unit can raise the water. Raising water from a well or well is energy costs determined by the technical capabilities of pumping equipment.

Other building codes:

- Straightforward laying of water pipes from the source of water intake to the house is a priority. Deviations from a straight line are not prohibited if insurmountable obstacles are encountered on the way. For example, a tree, a constructed object, and so on.

- It is better to lay the gasket below the level of soil freezing. This is not a strict standard, because pipes can be thermally insulated, since the market offers several effective and inexpensive technologies.

- If the water supply is organized from central networks, a well must be organized near the connection point. A shut-off valve and a water meter are installed in it. The well must be insulated so that neither the pipe nor the water meter will freeze in winter.

- Wells and wells, which are sources of water intake, should be located at a distance of 50 m from cesspools, gutters, septic tanks, filtration fields.

Taking into account all the requirements, it is important to carry out the design correctly. Pipes are selected according to the diameter of the product and the material from which they are made.

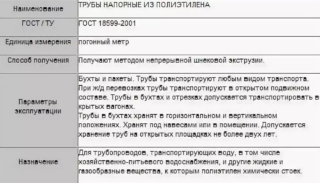

Choice of pipes

- high plasticity, hence the ability to lay a water supply system without using additional fittings;

- low abrasion;

- high strength;

- withstands water temperatures up to + 40C;

- does not corrode;

- in the process of freezing, polyethylene does not crack or deform;

- service life - 50 years;

- low price;

- ease of installation.

Pipes are sold in coils 50 or 100 m long. When buying, you can cut off the required amount from the coil.

Installation steps

The organization of external networks and water supply facilities begins with marking on the ground exactly according to the manufactured project. Further, the excavation is carried out. The depth of the trenches to be formed is also indicated in the project. The width should be 0.5 m greater than the diameter of the pipe to be laid.

If the soil at the construction site is loose, the bottom and walls of the trench are leveled and compacted. Before laying the pipe, the bottom is covered with a layer of sand 10-20 cm thick, which is also leveled and tamped.

Pipes are laid out in trenches. At the junctions of pipe sections, for example, branches, a pit is made at the bottom of the trench. The very process of joining pipes is carried out in two ways: using fittings or welding. If the pipe used has a diameter over 150 mm, the connection is made with flanged fittings.

Welding technology is used more often: butt welding and electrofusion. Joint-to-joint is the most effective way to achieve maximum joint strength. But if the diameter of the laid pipes is less than 63 mm, electrofusion welding is the best option.

After the completion of the installation work, the thermal insulation of the water supply system is carried out. For this, special cylinders are used, they are also shells made by pressing various heat-insulating materials: mineral wool, expanded polystyrene, polyurethane foam, and others. Heaters of this type consist of two or three parts, which they cover the pipe and fasten together with knitting wire or clamps.

Another option for thermal insulation of an external water supply system is a heating cable. It is under low voltage all the time, so it constantly emits heat. The only drawback is volatility.

Plumbing testing

Any pipe connection cannot guarantee 100% leakage protection. Therefore, the water supply network is tested before installing the thermal insulation. Algorithm of ongoing processes:

- the entire plumbing system is filled with water without pressure and is in this state for 2 hours;

- pressure is created inside the pipes, which is maintained for half an hour;

- the water supply system is checked for leaks, special attention to the joints.

The final stage after the installation of the heat-insulating material is backfilling the trenches with soil. It is preliminarily recommended to fill the pipe with sand with a layer thickness of 15-20 cm, then fill the trenches with the selected soil. Without fail, the plumbing system is flushed until the water at the outlet is clear.