A water valve is a shut-off valve designed to completely stop the movement of water in the water supply network. Most highways with a cross section from 15 mm to 2 m are equipped with such devices for various liquids: water, oil products, as well as compressed air and bulk products.

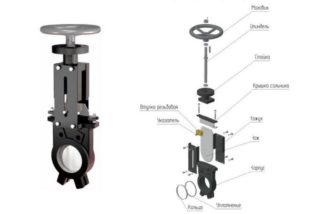

Gate valve design

- body part with a lid;

- shut-off unit, which includes a guide and a shutter;

- control element consisting of a valve, a flywheel and a threaded sleeve;

- yoke assembly for protection against aggressive environments and high temperatures.

The devices are made from ductile iron and steel. They are fixed in the system by means of a flange or coupling threaded (for pipes with a small cross-section) connection.

The dimensions depend not only on the purpose and type, but also on the material of manufacture. The standard diameter of cast iron products is from 40 to 2000 mm, face-to-face length is from 140 to 550 mm. Corresponding dimensions according to GOST for steel flanged gate valves: 50-1600 mm and 140-550 mm.

Operating principle

The pipeline valve works in this way:

- Manually or with the help of an electric drive, the flywheel moves, and behind it the rod.

- The stem moves the shutter controlled by the guide.

- The shutter baffles the body, creating an obstacle in the path of fluid movement.

To open the shutter, you need to turn the flywheel in the opposite direction.

Do not use valves to regulate the water flow. This function is performed by special valves for water supply. In valves used not only for complete shut-off, steel or cast iron parts, with constant exposure to liquid, will gradually wear out and will not be able to perform their work efficiently.

Types of reinforcement elements

Gate valves are divided into two types depending on the direction of action - parallel and perpendicular. The last type is stationary, moving at an angle of 90 degrees to the stream. Parallel units are set at zero angle and do not obstruct fluid while in standard mode.

Reinforcement elements are classified according to the type of constipation:

- wedge;

- hose;

- shiberny.

Also, shut-off valves differ in the method of shutting off the pipeline: with a retractable and non-retractable spindle. In the first version, there is a translational transmission of the flywheel rotation, the subsequent extension of the spindle and the overlap of the pipe gap, in the second, the closure is carried out only by rotation.

Devices installed on equipment for extinguishing a flame can be distinguished into a separate category. Fire dampers are inclined with an external thread or with a flange entry and reduction.

Criterias of choice

Before purchasing a reinforcing element, it is determined what it will be used for: to completely block the water flow or adjust it. After that, the following indicators are analyzed:

- purpose and operating conditions: quality of the working environment, pressure maxima and temperature range;

- nominal size of conditional passage (DU);

- way to control the device;

- dimensions and methods of connection to the pipeline;

- overlapping device option;

- suitable body material.

The cast iron gate valve is most often used for sewer pipelines, pipelines with compressed gas, steam and bulk products.For heating and water supply networks, steel shut-off elements are mainly used.

The cost of the device depends on the technical characteristics. The range of prices is very wide: valves can cost from 1,000 to 140,000 rubles. Prices for water control valves range from 1,000 to 500,000 rubles.

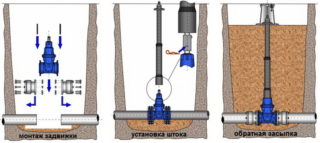

Installation features

- Cut the pipe to the required length.

- The connecting pipe of the valve and the end of the pipe are put on the nozzles of the soldering iron heated to 260 degrees.

- After heating, a pipe is inserted into the branch pipe.

- Allow the compound to cool and completely cure the plastic.

The flywheel can be located either from the top or from the side, but never from the bottom.

If the line is metal, the installation depends on the type of connection of the fittings. You will need to cut threads at the ends of pipe sections or weld mating flanges.

The installation of electrically driven valves on water pipes has its own nuance. The element is mounted in any position, except for the bottom one. If the spindle is located in a horizontal plane, additional support for the electric drive is required.

Most of the gate valves cannot be repaired. The condition of the valve should be carefully monitored and, if necessary, replaced with a new one.