An autonomous source of water supply in a suburban area is a good alternative to centralized communication. More often, craftsmen prefer to equip a well or a well. With proper installation and operation of sources, their flow rate remains constant. But there are often cases when a hydraulic structure in the lower part is overgrown with silt, which leads to a decrease in its productivity. If the well is silted up, it must be cleaned out. There are several flushing methods. It is important to choose your own in accordance with the available opportunities and finances.

Signs of siltation

The problem of silt fouling of the source more affects sand wells. This is a feature of their design. Grains of sand that overcome even the finest filter mesh, sooner or later, densely fill the lower part of the casing. This prevents the free flow of water into the mine. The sure signs of silting up the source are - a decrease in flow rate (especially after the winter idle of a hydraulic structure) and an admixture of a large amount of turbidity and sand in the water.

Silt fouling is also typical for an artesian well. But such phenomena are more rare.

The main causes of the problem

Sanding, and then silting of the lower part of the hydraulic structure occurs with the following provoking factors:

- Operation of the source for periods. If the well is used only for seasons, the alternation of the flow rate from below by itself provokes the sedimentation of the sludge on the filters. With a strong pumping out of the liquid, its volumes seem to randomly wash the mesh. Once the flow stops, all grains of sand slowly settle to the bottom and form a dense muddy crust.

- Incorrect installation of the bottom of the casing. If it is located outside the zone of the aquifer or in that part of it where water arrives more slowly, sooner or later there will be problems with clogging of the filter, since the dynamics of fluid movement is extremely low here.

- Incorrect pump position. If it does not reach the bottom (normally 1 m from its lowest point) and, moreover, has an upper fence, silting cannot be avoided.

- The use of rotary pumping equipment, which must not be lowered below the 10 m mark. In such situations, all agitated particles of clay or sand settle to the bottom.

An important factor is the complete tightness of the casing. If a column is damaged in an artesian well, soil, sand and clay can ooze into it along with groundwater from the upper horizons.

Methods for cleaning wells from silt

You can clean the well from silt on your own or invite specialists for this. It all depends on the depth of the source and the scale of the problem.

Cleaning with a bailer

This is the simplest home-made method that allows you to clean shallow hydraulic structures (up to 15 meters). Deeper than one can no longer cope. To complete the work you will need:

- durable winch (preferably electric);

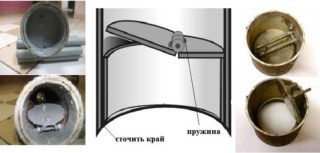

- a cut of a steel pipe with teeth at one end and special flaps (bailer);

- the pump is powerful, the most efficient (can be drainage or fecal) for pumping out water contaminated with sludge.

The work is carried out in the following sequence:

- Pump out water from the source to the maximum.

- The winch is installed strictly above the well.

- Attach the bailer to it with the prongs down. Its diameter should be less than the section of the casing.

- With force (with a free fall from a height of about 1-1.5 m), a steel flask is lowered to the bottom of the source. Upon hitting the sludge, the thief flaps will open and capture some of the impurities with water. As the flask rises, the blades will close and prevent dirt from entering the shaft again.

Thus, they act until the volumes of the lifted sludge decrease significantly.

When working with a thief, a pump is turned on in parallel to pump out the loosened water. The work is carried out continuously until the purest liquid flows from the well.

Using the airlift

This method involves the use of a dedicated compressor. To begin with, a pipe of a smaller section is installed in the casing. Compressed air is already fed into it, which will loosen the silt deposits and thus clean the bottom of the source. Water mixed with air and sludge is converted into foam, which is pushed upward when the pressure is changed at the bottom.

Doing such work on your own is relatively difficult. Here you need to have certain skills and control the water level in the inner pipe.

When pumping out a silted volume, a tank with a sieve or a mechanical filter can be installed next to the hydraulic structure. By draining a resource here, it is cleaned of impurities and then used for technical purposes or for watering.

Mechanized cleaning method

You will need two types of pump - one for supplying clean liquid under high pressure to the bottom of the well, the other - drainage pump for pumping out silted water from below. Both units are turned on at the same time. Moreover, the drainage pump must be placed as close as possible to the bottom of the source. The supply of clean water under pressure is done from about 50 cm from the bottom point of the column.

Fire truck help

This method is suitable for those who are confident in the strength of the casing with a filter and have enough funds to rent equipment. The principle of cleaning the source consists in supplying a stream of water into the well through the fire hose and the same reverse pumping of the liquid with sludge. The time for flushing with the help of special equipment takes up to half an hour. But if the elements of the well are flimsy, there is a risk of damage to them. It is convenient to clean a hydraulic structure in this way.

Comprehensive source cleaning

Several methods are used simultaneously to clean up the source. First of all, water and all large debris are removed from the mine as much as possible. Then, under high pressure, water is fed into the column, eroding the silted bottom. At the same time, a powerful pump is used to pump out the dirt. The next step is to rinse the filter and pipe with special reagents or acids.

It is important to take into account that improperly selected proportions of chemicals can be harmful to health. Basically, professional drillers work with acids and reagents.

In conclusion, a water hammer is performed using special equipment. It removes the remains of sludge, used chemicals.

Prevention of siltation

To prevent the formation of a sandy-organic crust from the bottom in the well, a number of preventive measures must be taken:

- Follow the established drilling technology and ensure that the casing is completely sealed.

- Thoroughly pump the well after its installation until absolutely clean water appears.

- Mount the head and protect the shaft from atmospheric precipitation and small debris.

- Correctly mount the submersible pump, observing the optimal depth (one meter from the bottom), which does not allow sand to silt up the filter mesh.

- Use only a vortex or centrifugal pump, not a vibratory pump.

- Operate the source constantly to ensure dynamic fluid movement in it. If the residence on the site is seasonal, it is better to pump out 100 liters of water from the well every month.

Subject to such recommendations, the hydraulic structure will not cause problems to the owner, and will not become silted up.