Industrial and domestic water supply systems operate thanks to reliable pumping equipment. But even it can break. In order for the system to start functioning again, it will be necessary to purchase spare parts for water pumping stations, which will allow the unit to be repaired and continue to operate.

Basic spare parts for pumping stations

The accumulator is a metal tank divided into two parts by a rubber membrane, also called a pear. Water is pumped into it. On the other side of the tank, there is a fitting with a nipple through which air is pumped. Under the influence of water, the pear expands, compressing the air behind it. Thanks to this design, the fluid is under pressure, which helps to reduce the number of starts of pumping equipment and prolongs its life. A flexible hose for the pumping station is required to connect the hydraulic tank and the pressure head.

The check valve is installed on the supply pipe, which is lowered into a well or well. It prevents liquid from flowing back into the source.

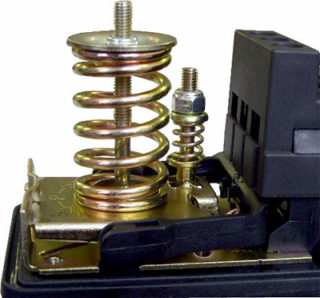

Control devices help maintain a constant pressure in the water supply network. The control unit includes a pressure switch and a pressure gauge. The first device turns on and off the engine, and the second monitors the fluid pressure in the network.

What needs replacement most often

Spare parts that can cause malfunctioning or stopping of the station:

- Hydraulic tank. Due to its malfunction, the pump works in jerks.

- Check valve. If it fails, the station works non-stop and may burn out.

- Relays and moving parts. If their regulation is violated, water from the station will flow intermittently.

- Contacts. If they are oxidized or burnt, the motor may not start.

- Capacitor. If it breaks down, the equipment will not work, it will hum.

All these parts need timely replacement as they wear out.

The most common failures are the elements that bear the greatest load: contacts, filter elements, diffusers, check valves, pressure switches.

Breakdowns in pressure equipment

A clear idea of which part needs to be replaced with a spare one, depending on the problems with the station, will be given by the table:

| Malfunction | Checked node | Elimination method |

| Water does not enter the system when the pump is running | Water level at the source | We lower the pump and the check valve to the required depth. |

| Check valve | We go through the filter, clean it. If the part is broken, we will replace it. | |

| Liquid in the pipe and impeller chamber | In the absence of water, top up. | |

| Pressure switch | We disassemble, check the inlet of the relay, contacts. We clean. Change the aperture if necessary. | |

| Relay setting | We set the upper and lower pressure limits by means of small and large springs. | |

| Pear | We determine the air pressure, if necessary, install a spare part. | |

| Air in the system | Add water to the impeller chamber. | |

| Noise during operation | Pump bearings. | We replace defective parts. |

| Low water pressure in the system | Impeller for wear. | |

| Leaks | The integrity of the rings and collars of the fitting elements. |

If it is necessary to replace the bearings, it is better to take the pump to a service center, where the breakdown will be eliminated with a guarantee. In case of leaks due to a worn-out rubber band or a clogged filter on the check valve, the malfunction can be completely eliminated by yourself.

Do-it-yourself troubleshooting

Troubleshooting methods at a self-service station:

- Electricity voltage drops in the power grid. If they occur regularly, we feed the pressure equipment through the stabilizer.

- Insufficient pressure in the accumulator. We drain the water through an open tap and pump the air with an automobile pump to 1.5-2 atmospheres. Check again.

- The well has a low water level. To confirm this, we take out the suction pipe with a non-return valve, measure the length of the pipe section in the well with a tape measure. Finding out the water level. To do this, we lower the cord into the well with the bottom upwards tied to the saucer. As soon as it touches the "mirror", the tension will weaken. Compare the lengths of the pipe and the length of the cord to the water surface. The check valve must be three meters below the water "mirror" in the well.

- The suction pipe does not hold water. We disassemble the non-return valve, inspect the plastic guide, in case of failure, install a new part. If there is no damage, rinse and install back.

- The pipe that sucks in the water is not tight. We carefully inspect all connections, sequentially disassembling the element. We check the integrity of the rubber rings, change if necessary. We carry out an additional check of tightness by pouring water.

- Air in the pumping cavity. Unscrew the plug at the top of the impeller chamber and add water through the funnel until it flows over the edge. We restart the equipment.

- Air exits through an oil seal on the pump shaft. We replace the part by removing the flange on the shaft.

- Diaphragm ruptured. We unscrew the nipple from the air connection of the accumulator. If water flows out of it, replace the pear.

The latter problem arises in stations quite often. To replace the membrane, you need to disassemble the tank. Before doing this, release the pressure in it by shutting off the water supply and drainage of the residues, then disconnect from the power supply. Further actions are performed in the following sequence:

- loosen the flange mounting bolts, drain the water;

- remove the flanges;

- take out the diaphragm;

- we wash the tank;

- insert the membrane into the accumulator;

- straighten the neck and tighten the flange, tightening the bolts from opposite sides;

- we connect to the water supply and electrical network and check the operation of the equipment.

A new membrane for a pumping station costs 200 rubles and more.

If the diaphragm element is not worn or torn, the air pressure is correct, it is recommended to check the relay. First, the setting is set to shutdown. To do this, completely loosening the small one, we reduce the tension of the larger spring until the indicator of the manometer is 2.5–3.0. We adjust the small spring to turn on the pump, gradually tightening it. The pressure gauge should show 1.7-1.8. The non-working part needs to be replaced. The cost of a new pressure switch is from 200 rubles.

Often such an element as a diffuser flies in the equipment - a part of the pump that serves to direct the liquid and to convert high-speed water energy into a pressure force. The reason for this is the large volume of abrasive impurities in the pumped water. It is not difficult to change it. You just need to turn off the power supply and remove the front of the pump. The average cost of a diffuser is 700 rubles.

How to choose components

In modern storage tanks, replaceable membranes are most often installed. Sometimes the hydraulic accumulator is equipped with a non-removable diaphragm. The price of such drives is lower. But if the membrane becomes unusable, the entire tank will have to be changed completely.

Before buying, you need to make sure that the volume of the pear is suitable for the pressure equipment used, because membranes of a smaller volume than the calculated one will wear out and break faster. They will have to be replaced more often.

When choosing a membrane, you also need to take into account the quality of the rubber. It should be dense, strong, with no signs of cracks. The durability of the material is also important when buying a new diffuser. In addition to the diameter, it is also taken into account when replacing the suction pipe. The best qualities are polymer products and crease-resistant flexible reinforced hoses.

When choosing a pressure switch, it is necessary to take into account the peculiarity of a specific water supply scheme, primarily the indicators of the hydraulic tank and pumping device.

Each water pump has a different design and connection method. Parts for some devices are rarely suitable for mounting on other devices. It is very difficult to put a part from the Whirlwind pump on the DAB AQUAJET. Therefore, when choosing a new element, you should study its labeling and characteristics.