For the full functioning of a seasonal suburban area, it is advisable to make a winter water supply in the country. Then the rest will be comfortable even in the cold season. It is not difficult to assemble the communication on your own. The main thing is to know the basic principles of the system design.

Features of the installation of the highway

The winter water supply system is characterized by the following features of its functioning:

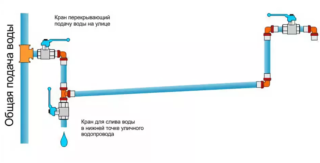

- The dacha system must be equipped with equipment for its conservation. If it is necessary to leave the owners for a long time, the liquid is simply drained from the pipes. This prevents the water supply from freezing.

- It is important to lay pipes only below the level of freezing of the soil or to make them high-quality insulation.

- When installing the highway, it is important to observe the slope from the house to the source (well / well). This will ensure the free flow of water and protect the pipes from stagnation.

- It is advisable to use a heating cable, which will additionally save the water supply system in the country from freezing temperatures.

Subject to all these rules, it is possible to make an anti-freeze water supply system in the country in 1-2 days.

Preparatory work

At the stage of preparation for installation, it is extremely important to draw up a plan for the entire wiring. This will allow purchasing the required footage of pipes and all the necessary components (fittings, taps, adapters). The points of the location of pumping equipment, plumbing zones in the house must be applied to the drawing.

Preparation includes digging trenches for pipe laying. The channels are made wide enough so that layers of insulation can be arranged in them.

It is also worth deciding on the type of source source - a well or a well. The following advantages speak in favor of the former:

- no blockages with long-term idle source;

- for water injection, you can choose a more affordable surface or submersible pump, but not an expensive deep one;

- installation of a well is always several times cheaper than a well installation.

It is best to deal with the installation of a winter water supply system in summer or early autumn, when the groundwater level is as low as possible.

Tools and materials

To lay a winter water supply system in the country, you should prepare the following tools:

- bayonet shovel;

- a special soldering iron for polypropylene pipes (they are optimal for street water mains);

- roulette;

- hacksaw for cutting pipes;

- Screwdriver Set;

- sealant.

Materials should be prepared:

- Pump equipment. It is advisable to choose a surface centrifugal pump and immediately equip it with a hydraulic accumulator.

- The required footage of pipes. Better to take polypropylene. They are as inert as possible to temperature extremes, aggressive environments, rodents, and corrosion.

- Drain valve. Provides drainage of water from the system. The drain valve is installed at the lowest point of the water supply system near the pump. It is advisable to take an electromagnetic element.

- Hydroaccumulator. For a family of 3-4 people, a capacity of 25-50 liters is enough. The diaphragm tank helps to maintain a constant pressure in the line. It is good if the accumulator is equipped with a pressure switch. It is this element that is responsible for the on / off cycles of pumping equipment.

- Connecting fittings. They are selected according to the number of turns of the highway.

- Shut-off valves.

- Insulation (cable, polystyrene cylinders, mineral wool, etc.).It is needed if the pipes cannot be laid below the level of freezing of the soil due to the peculiarities of the relief or the composition of the soil - rocky rocks, etc.

When buying tubes, it is advisable to make a small stock - to buy 10% more than the indicated footage. They will come in handy if you make mistakes at the time of installation.

Installation steps

- Land work. The bottom of the prepared canal must be tamped down and a sand cushion 10-15 cm thick poured onto it. It is also compacted.

- Pumping equipment is being installed. It is advisable to install the unit in an insulated caisson and on a special concreted area. This will eliminate vibration.

- A hydraulic accumulator is connected to the pump. In this case, a pressure switch must be installed.

- Hose and pipes are connected to the inlet and outlet of the pump using fittings. The first is designed to take water from a well. The second is the immediate beginning of the pipeline.

- Extend a line from the pump to the house or bath. The pipes are laid with a special soldering iron. For this, one end of the pipe is inserted into a nozzle of the required diameter. The end of the connecting sleeve is put on the second part of the soldering iron. Withstand 3-5 seconds and two elements are joined. It is important to insert the pipes into the fitting and twist them slightly. The molten polymer bonds well to form a strong, leak-proof bond.

- Insulate the pipes with the selected material. It is worth making sure that the insulation fits without gaps and cold bridges. Otherwise, because of them, condensation will appear, which will provoke freezing of the system. At the time of laying the insulation, it is important to take care of its high-quality waterproofing or to select a material that reacts inertly to water.

If mineral wool or polystyrene is used for insulation, it is advisable to cover them on top with a special coating of cement and broken glass. Otherwise, rodents in search of warmth can gnaw through the material in winter.

The last stage of the water supply system is its backfilling. The soil is laid loosely, without strong compaction. It is better to add soil later when it sags than to tamp the soil and risk breaking the entire system.

Common mistakes when installing a water supply system

- Lack of a drain valve. Without it, the water supply to the dacha cannot rightfully be called winter. The lack of regular drainage of water provokes the risk of freezing the line. This will sooner or later lead to its rupture.

- No slope or wrong direction. In the first case, water will stagnate in the system, which can lead to its freezing. In the second option, the liquid will flow not to the source, but to the house. With the taps closed, it will remain in the part of the highway that is closer to the building, and will freeze here at sub-zero temperatures.

- The use of the wrong materials and equipment: incorrectly selected pipes, insufficiently efficient pump, etc. If the material of the tubes is incorrect (steel, PVC), the line may burst, corrode, freeze. If it is about the pump, it simply will not supply the required volume of water to the family. Electricity will be consumed in this case. The risk of equipment burnout in such situations is high.

- Incorrect line deepening. If the master brought out inaccurate data on the level of soil freezing in the region, and did not use insulation to heat the system, most likely the line will freeze when the temperature drops in winter. To find out the exact level of soil freezing, it is advisable to use the SNiP tables or simply view the information on the Internet.

- Lack of a drawing of the laid communication. In the event of an emergency and in the absence of a line diagram, the master risks facing serious problems. We'll have to carry out a full excavation of the pipeline to fix the breakdown.

Winter water supply in the country is a guarantee of a comfortable stay outside the city in any season, regardless of the weather.